Hello,

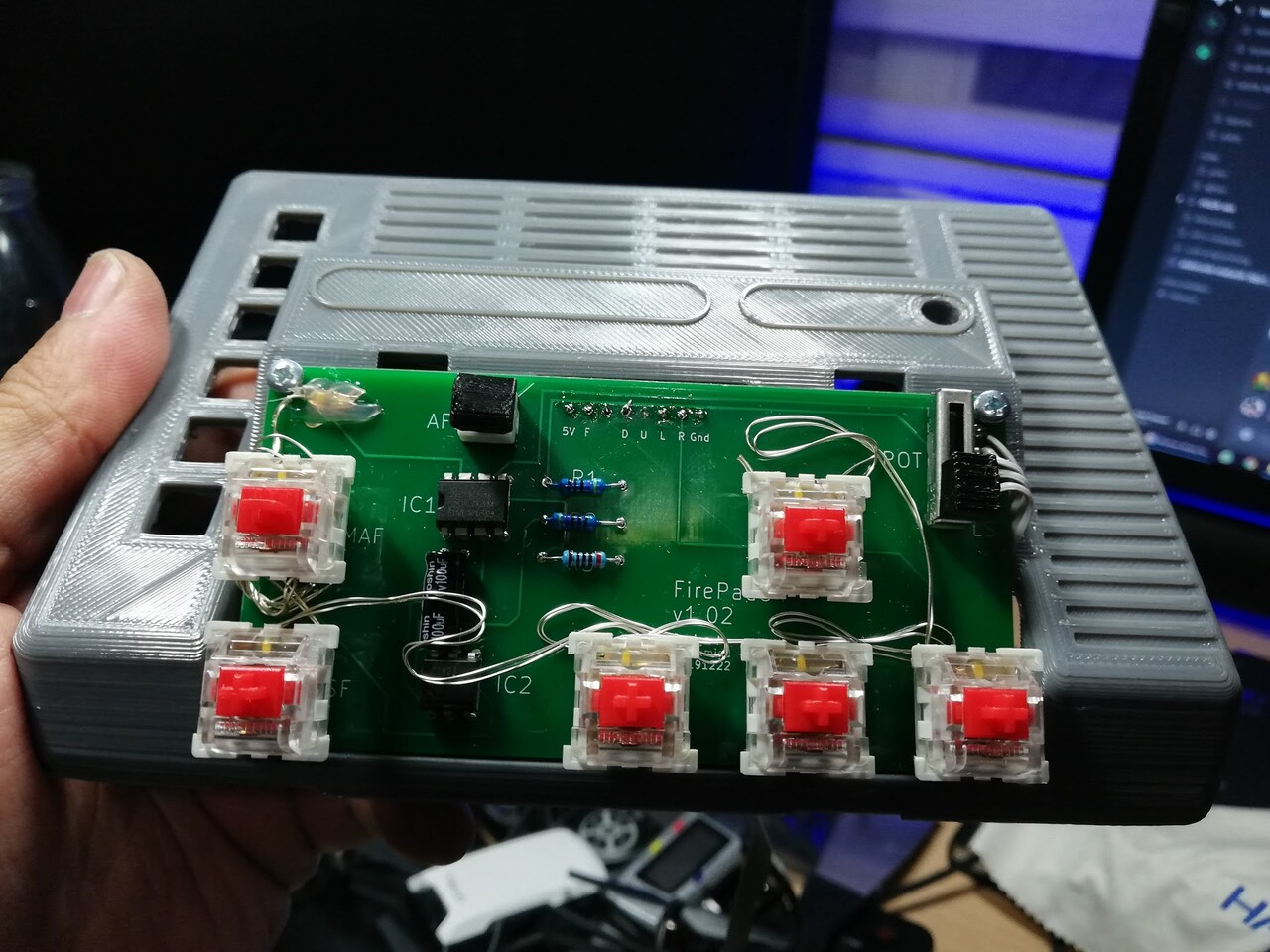

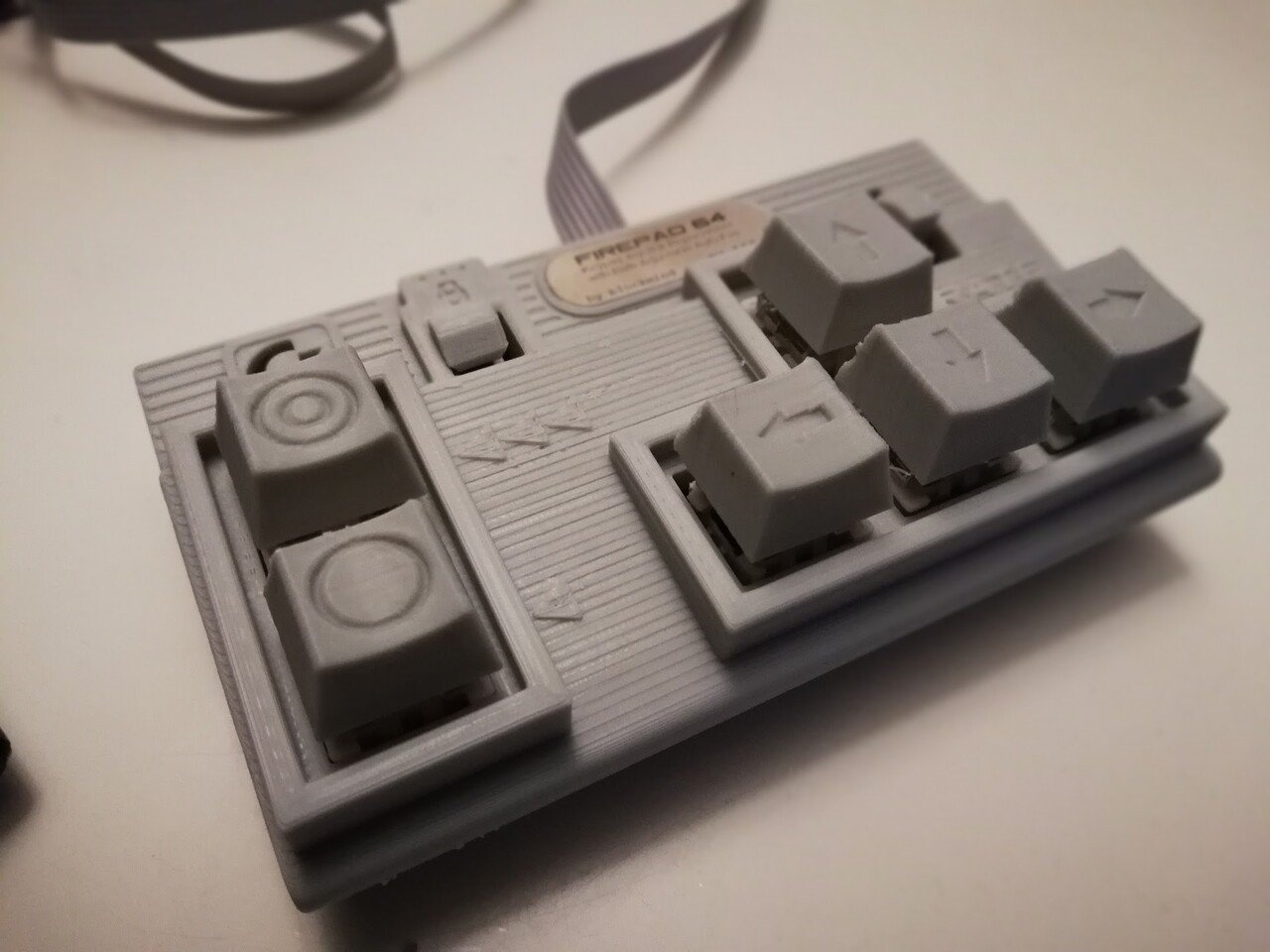

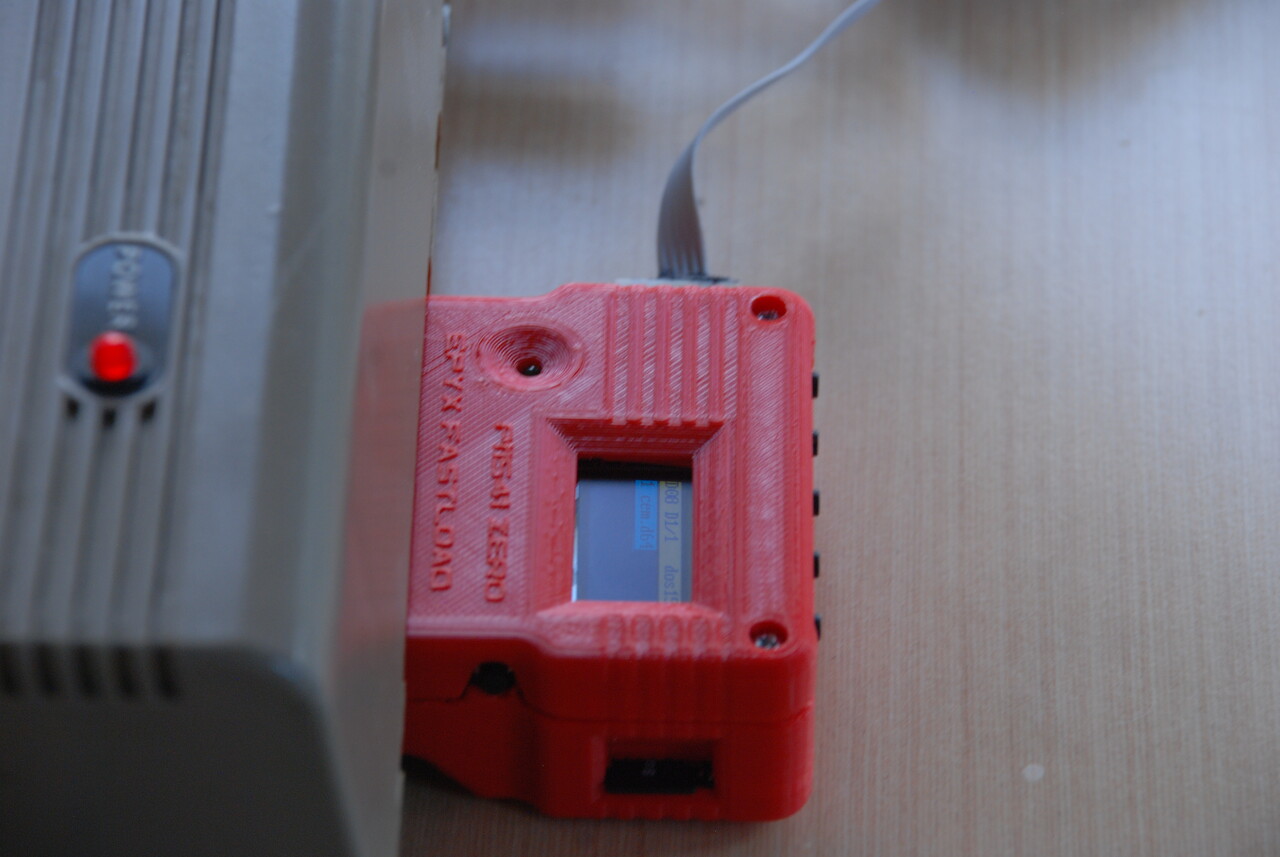

Recently I made an advancement on my Firepad64 design, which is the Version 3 (possibly the last update) for this device. It's a joystick replacement for Commodore 64 that has a keyboard layout for easy playing. You can check this post to see the first creation steps of this device:

https://www.artstation.com/blockmind/blog/zPLm/making-of-firepad64-joystick-replacement-for-commodore-64

I want to share the steps of the creation of this device because (except the PCBs) it's all homemade manufacturing which is a great achievement of our world has come to. I didn't even get out from home to create this "mechanic and electronic" product. So I find this important to share the details of creating an end-user product at home. It's cyberpunk! :)

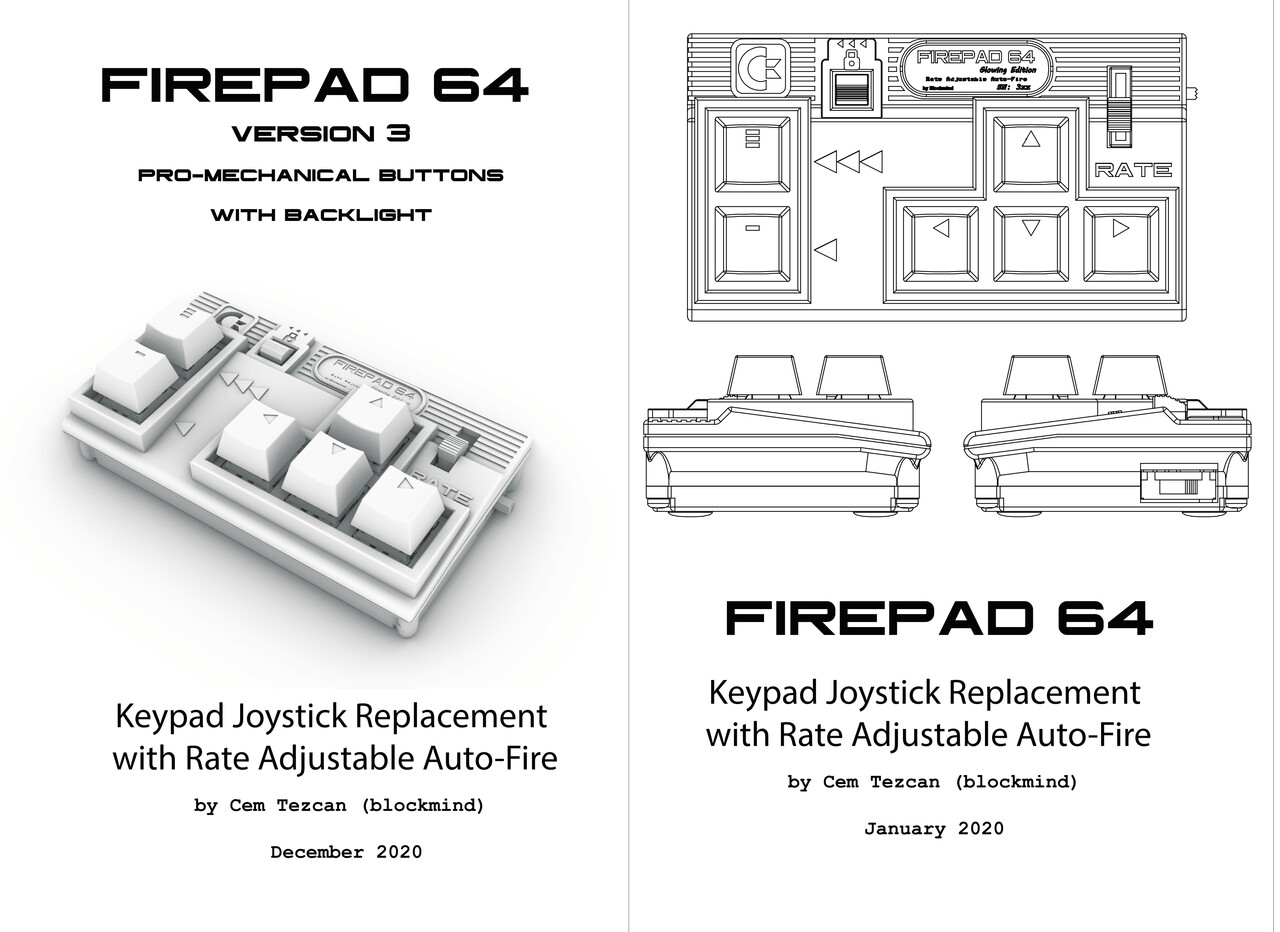

Anyway, Version 3 of Firepad64 has 3 major advancements after the previous version.

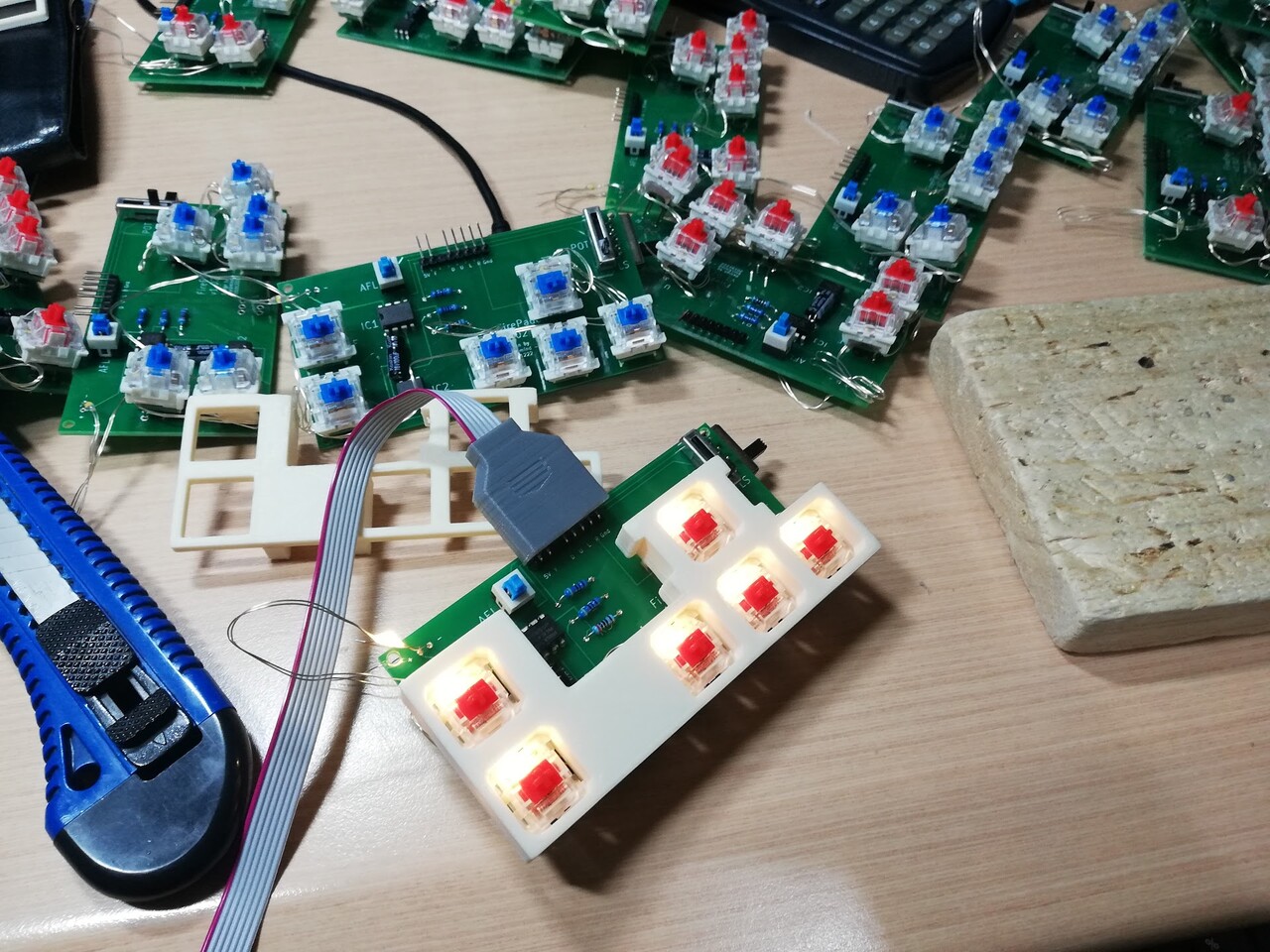

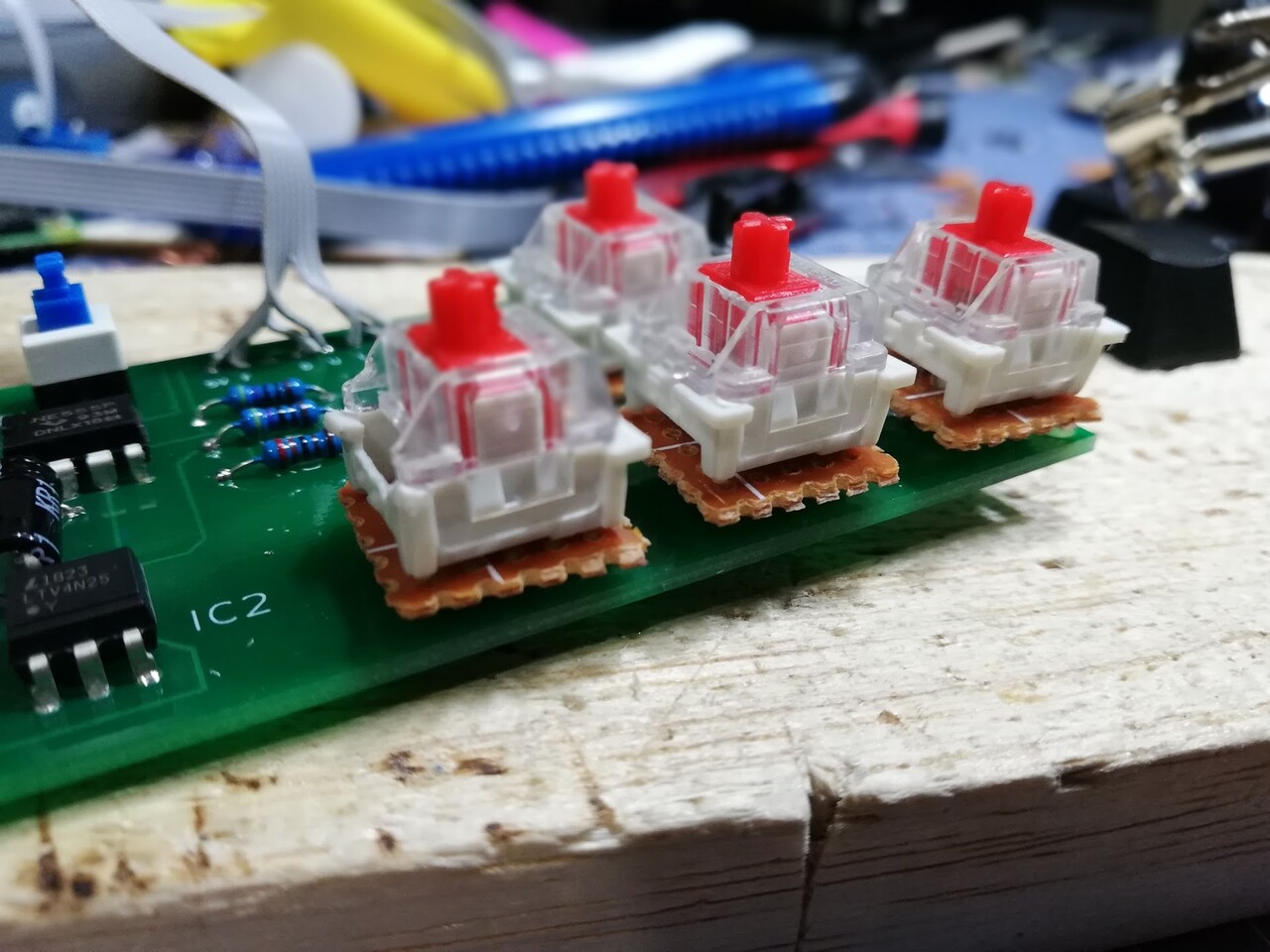

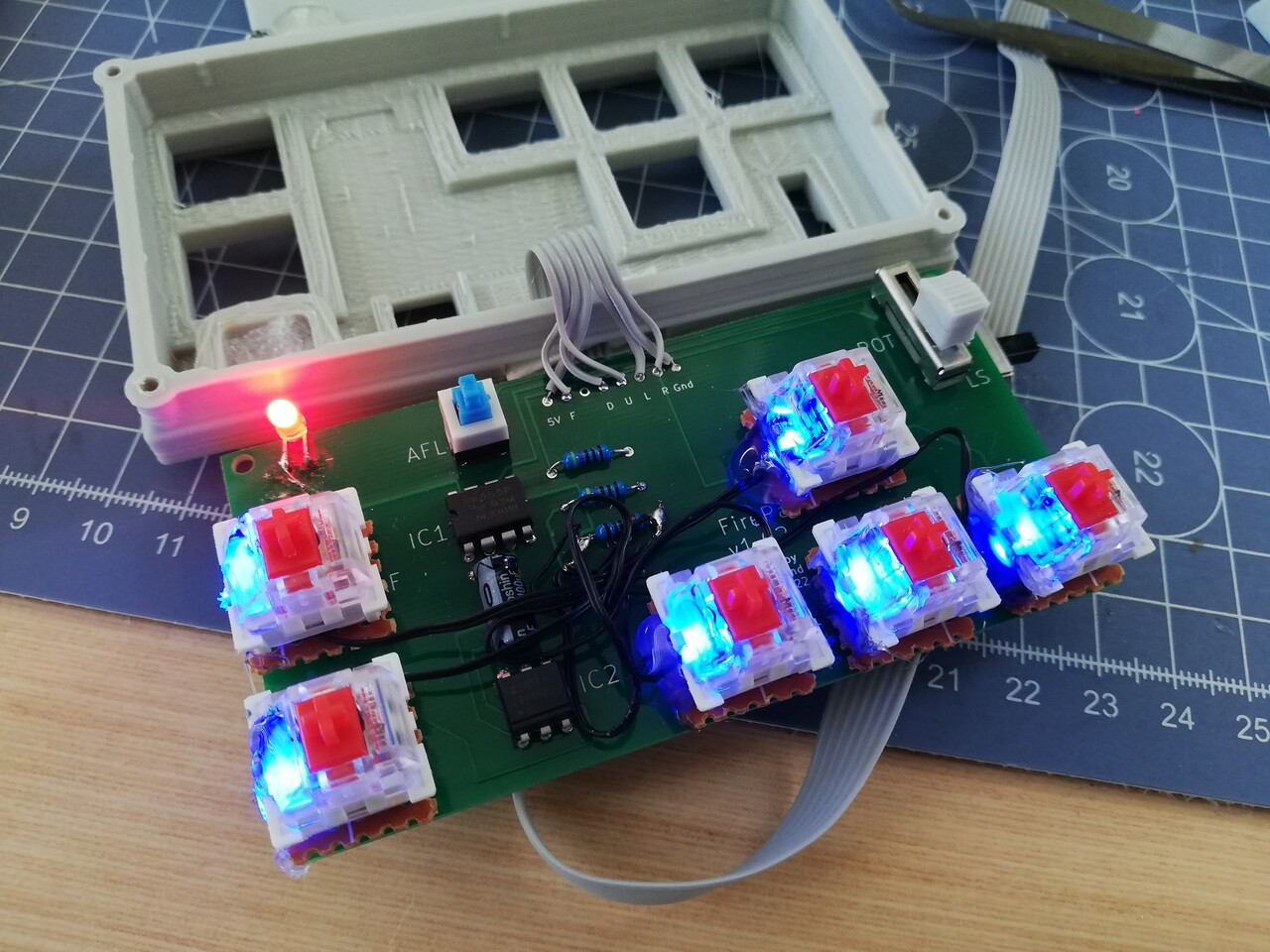

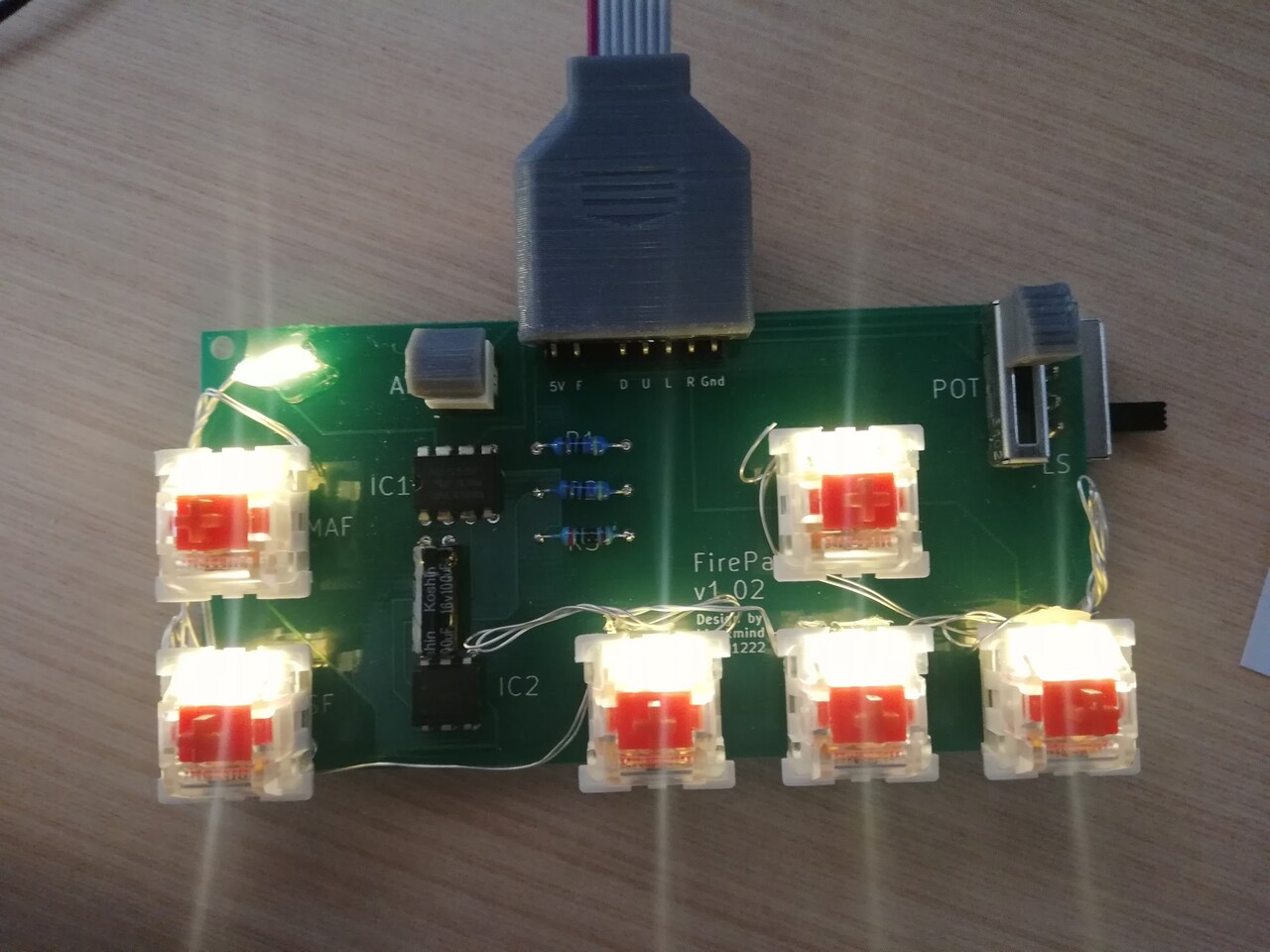

- Professional Outemu brand mehchanical keys with regular linear (red) and clicky type (blue) versions.

- Backlit Lighting

- Screw Assembly instead of shrink-fit

This video shows some details of the product but it's in Turkish.

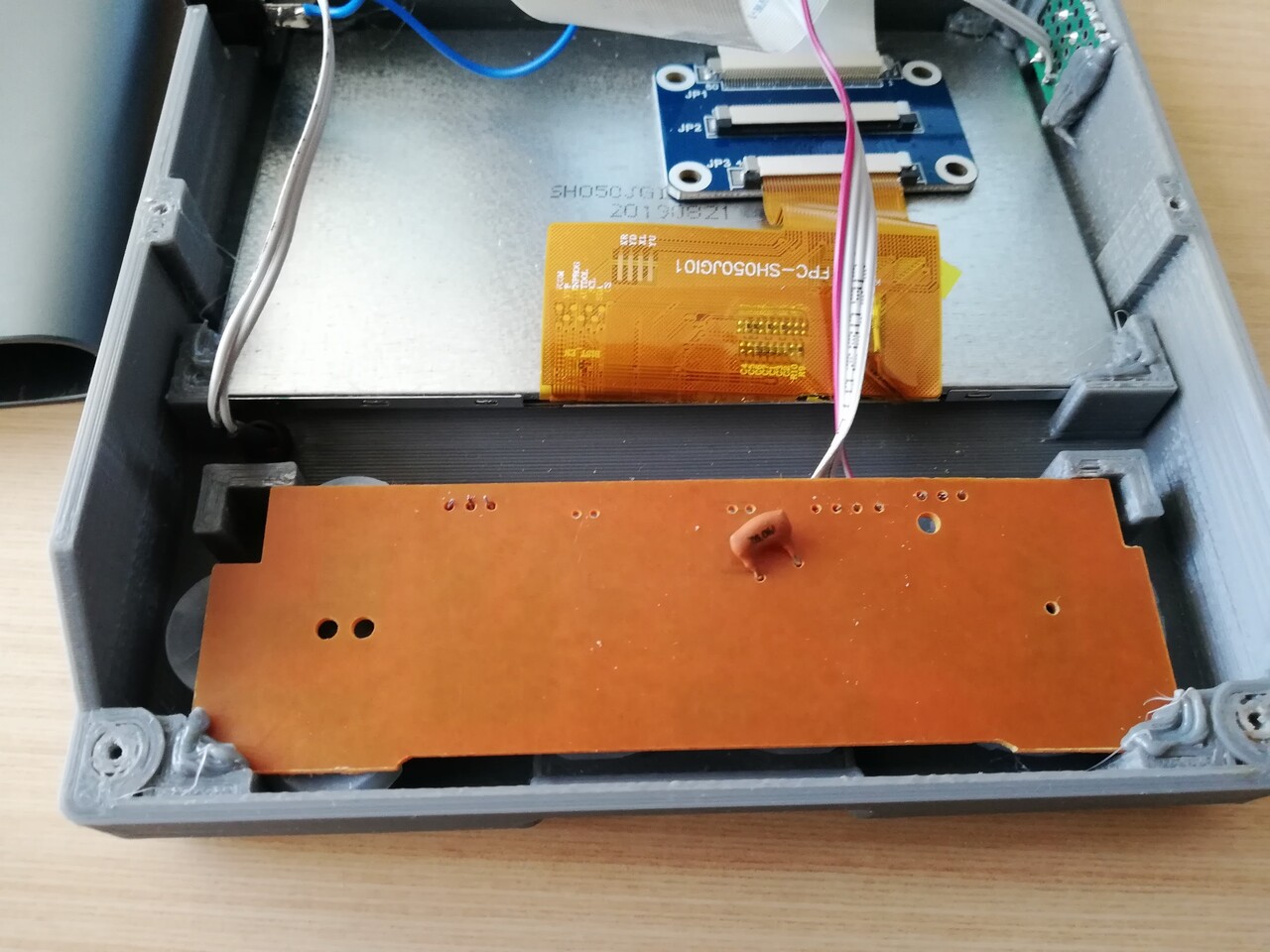

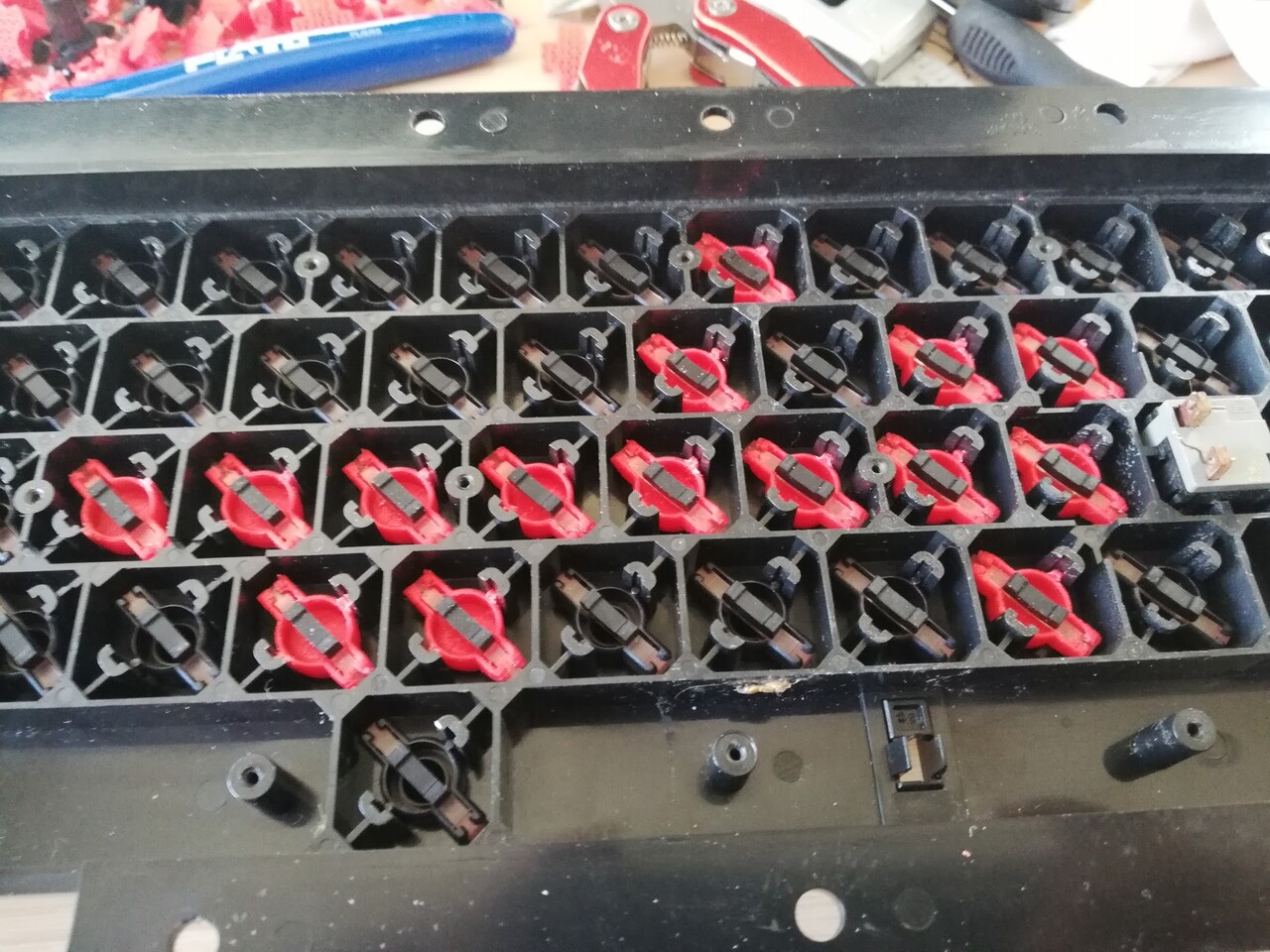

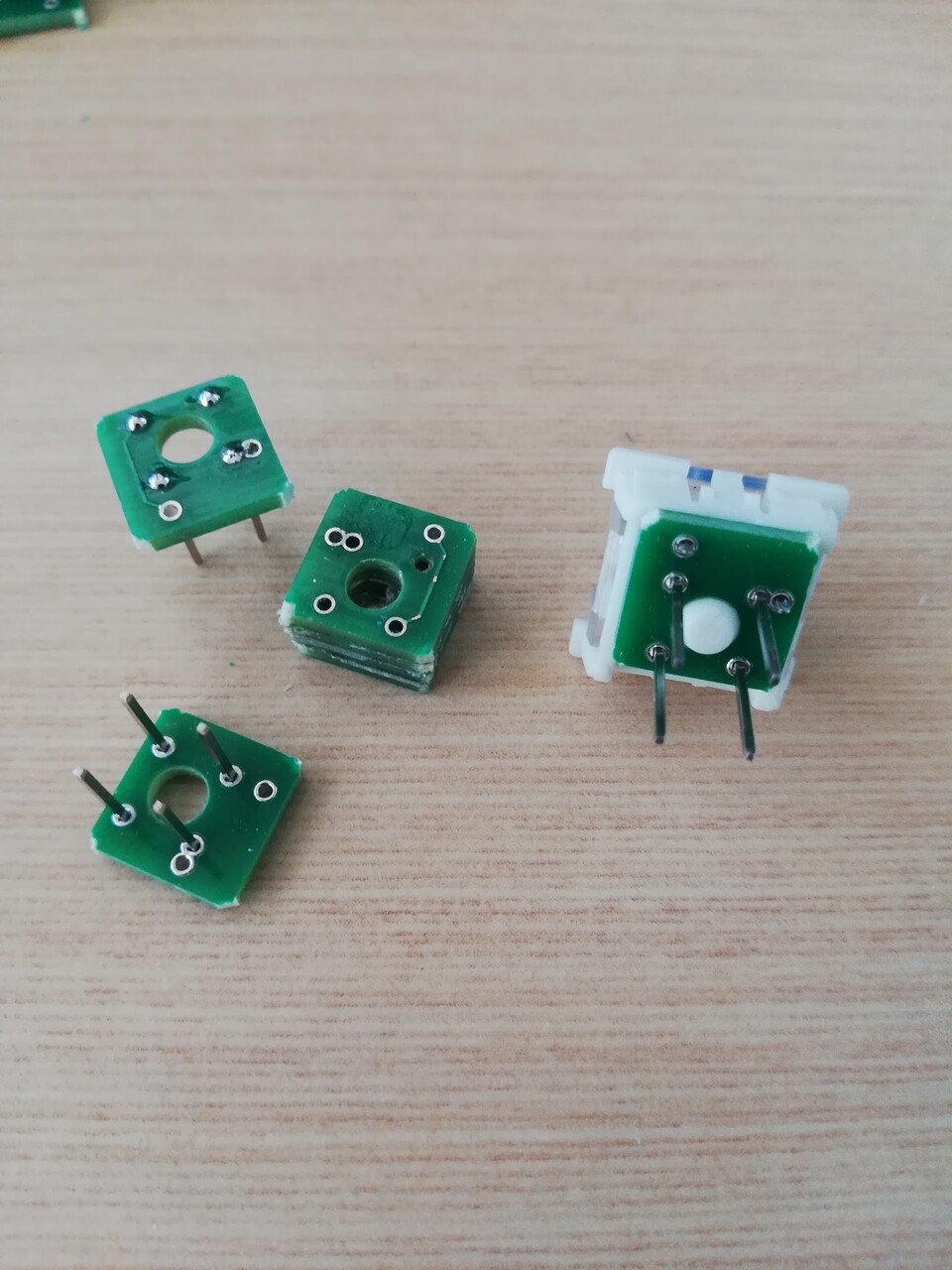

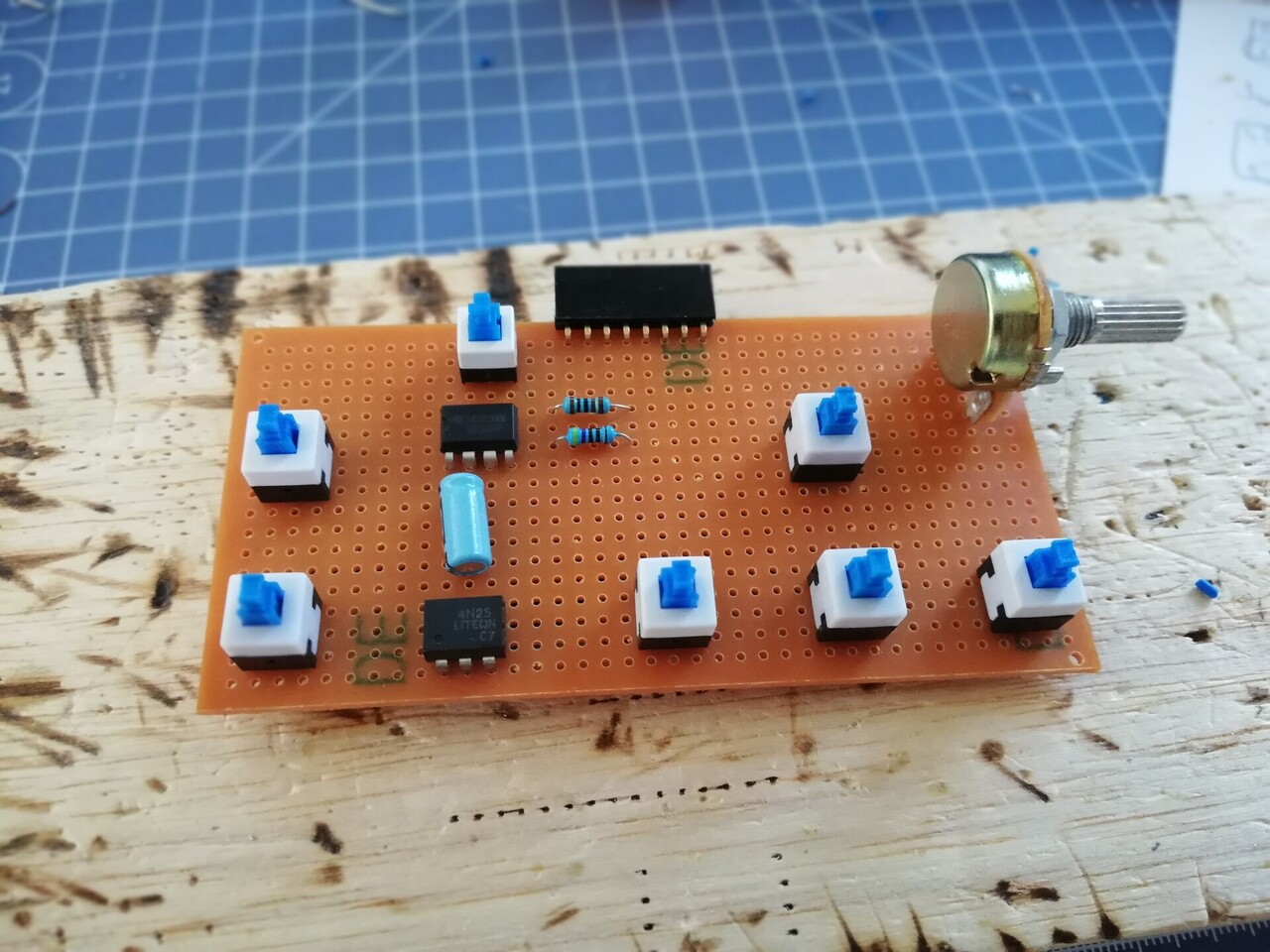

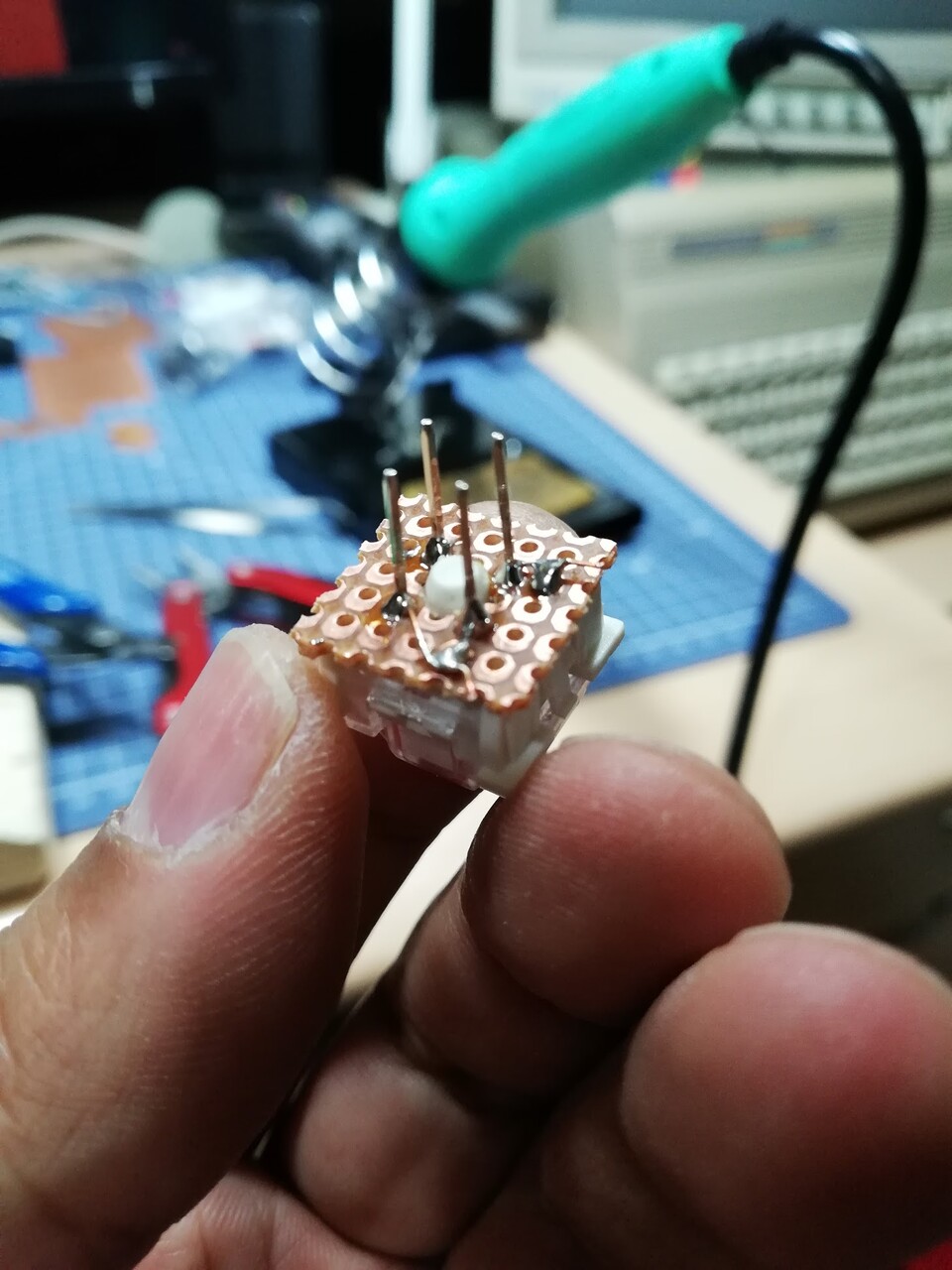

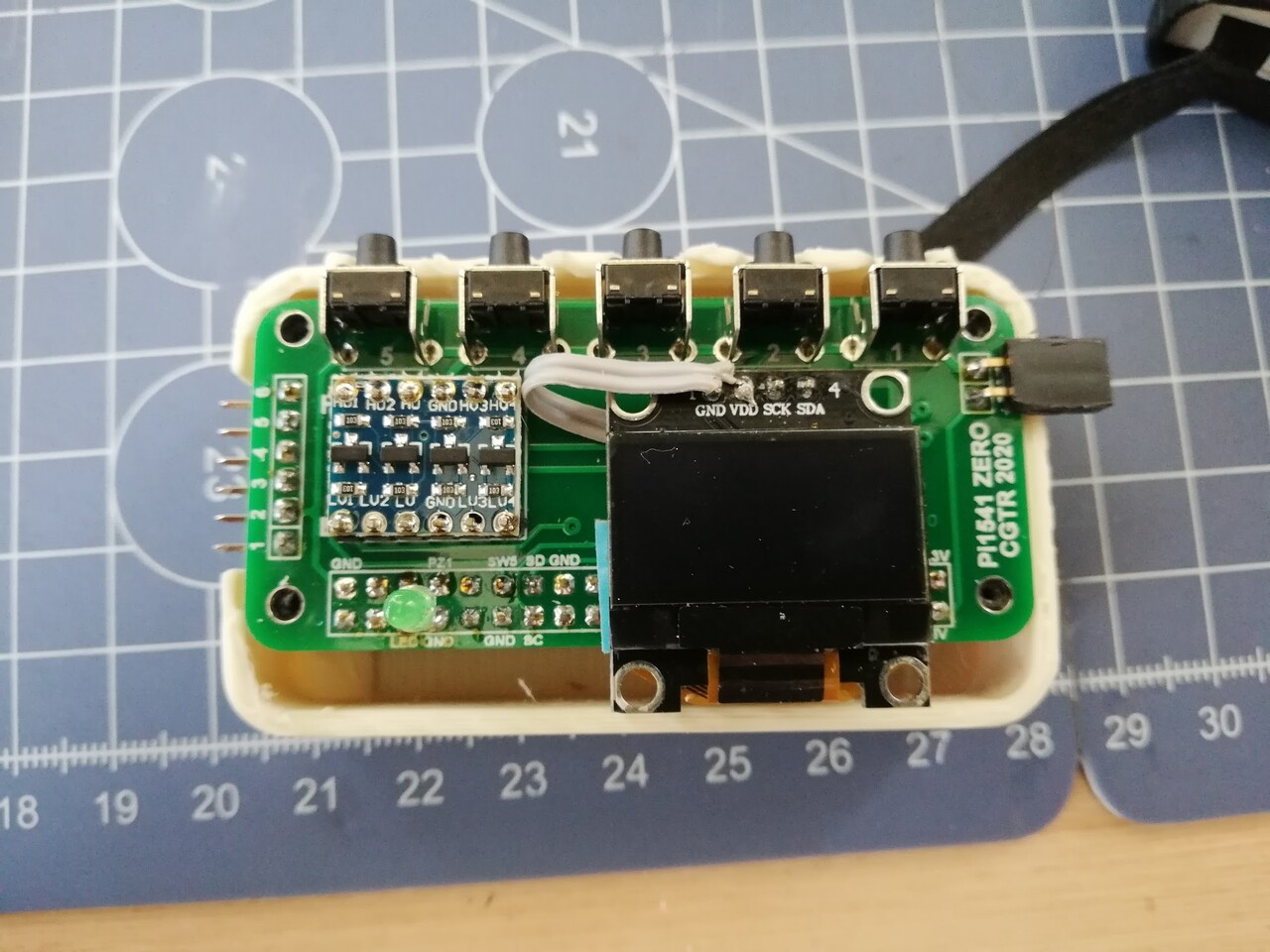

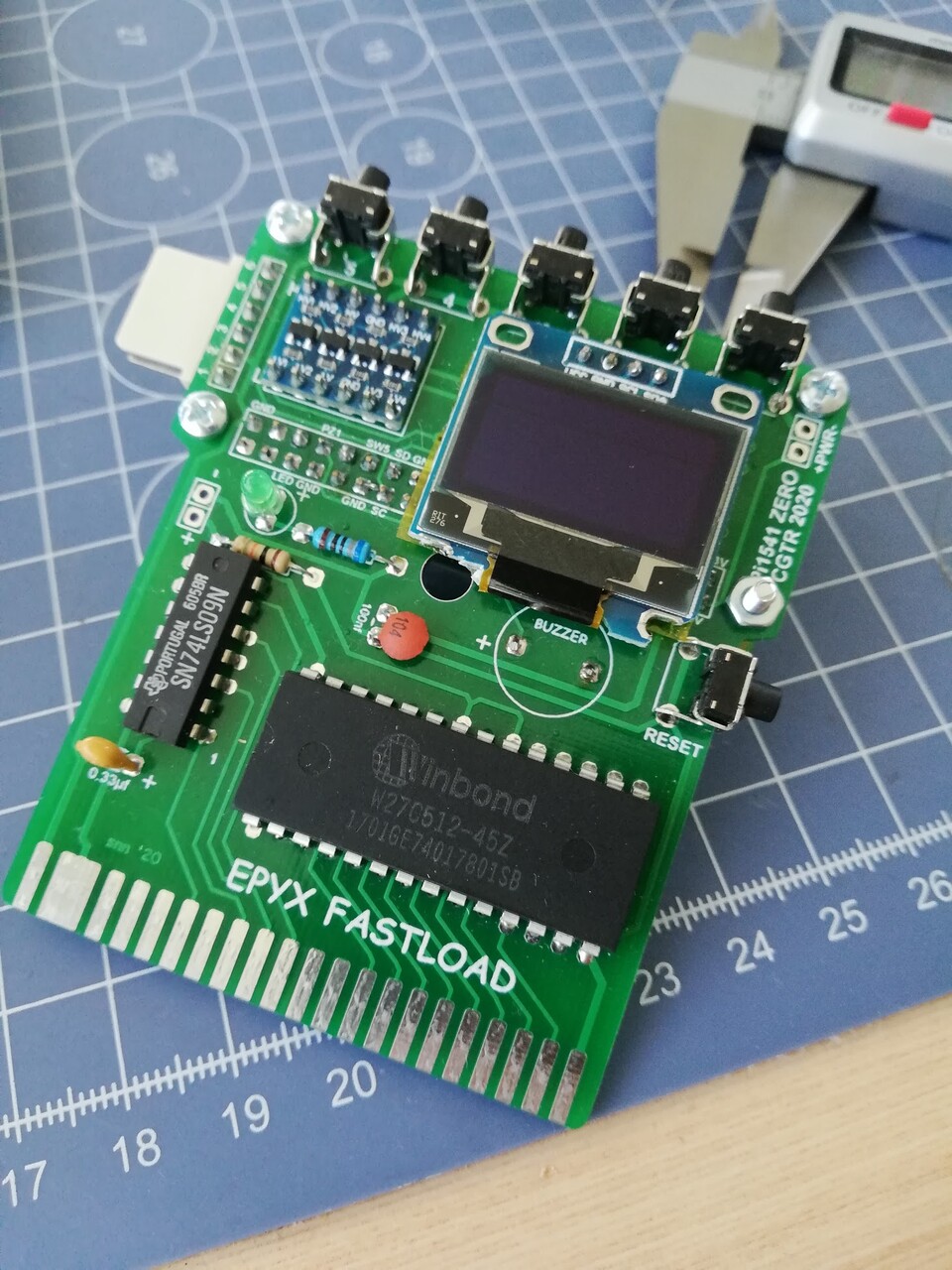

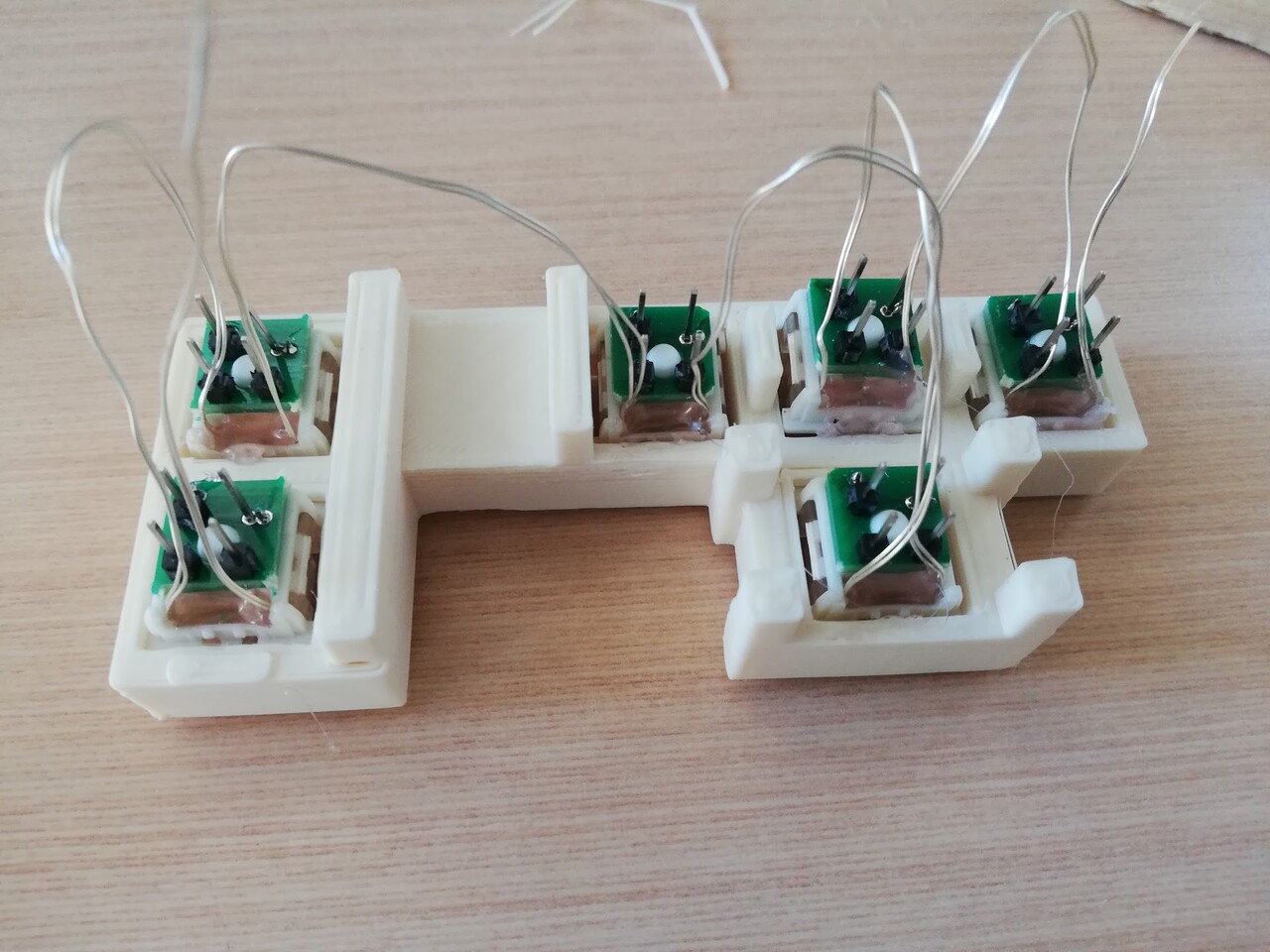

The most problematic part of this update was to adapt the Mechanical buttons to my existing PCBs. Because the pin positions are totally different. Since I have some 50 pieces of the previous PCBs, I decided made an adapter for the buttons to comply with my existing boards.

Without those adapters I was adapting the keys with prototyping boards. It was good for some 1-2 adaptations but it was not durable and it was so much time consuming to make the buttons adapt to my existing PCBs.

Wtih the help of the adapters it was easy for me to make usable mechanical switches in a fast way.

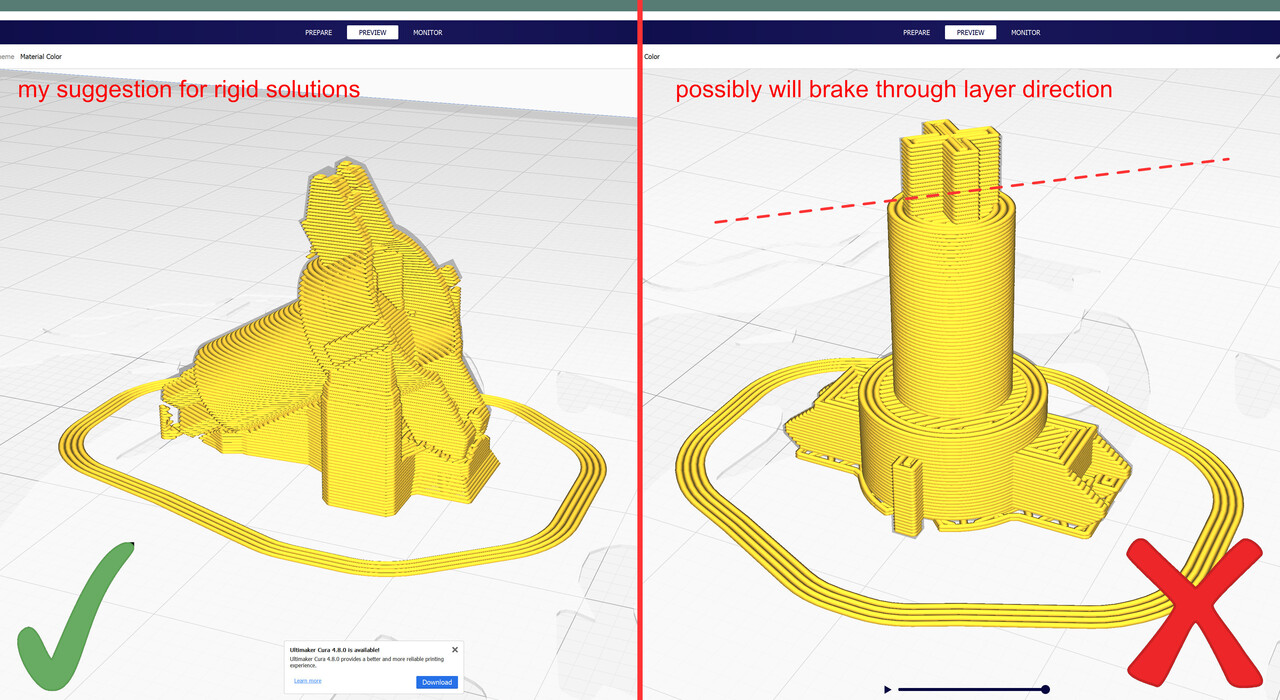

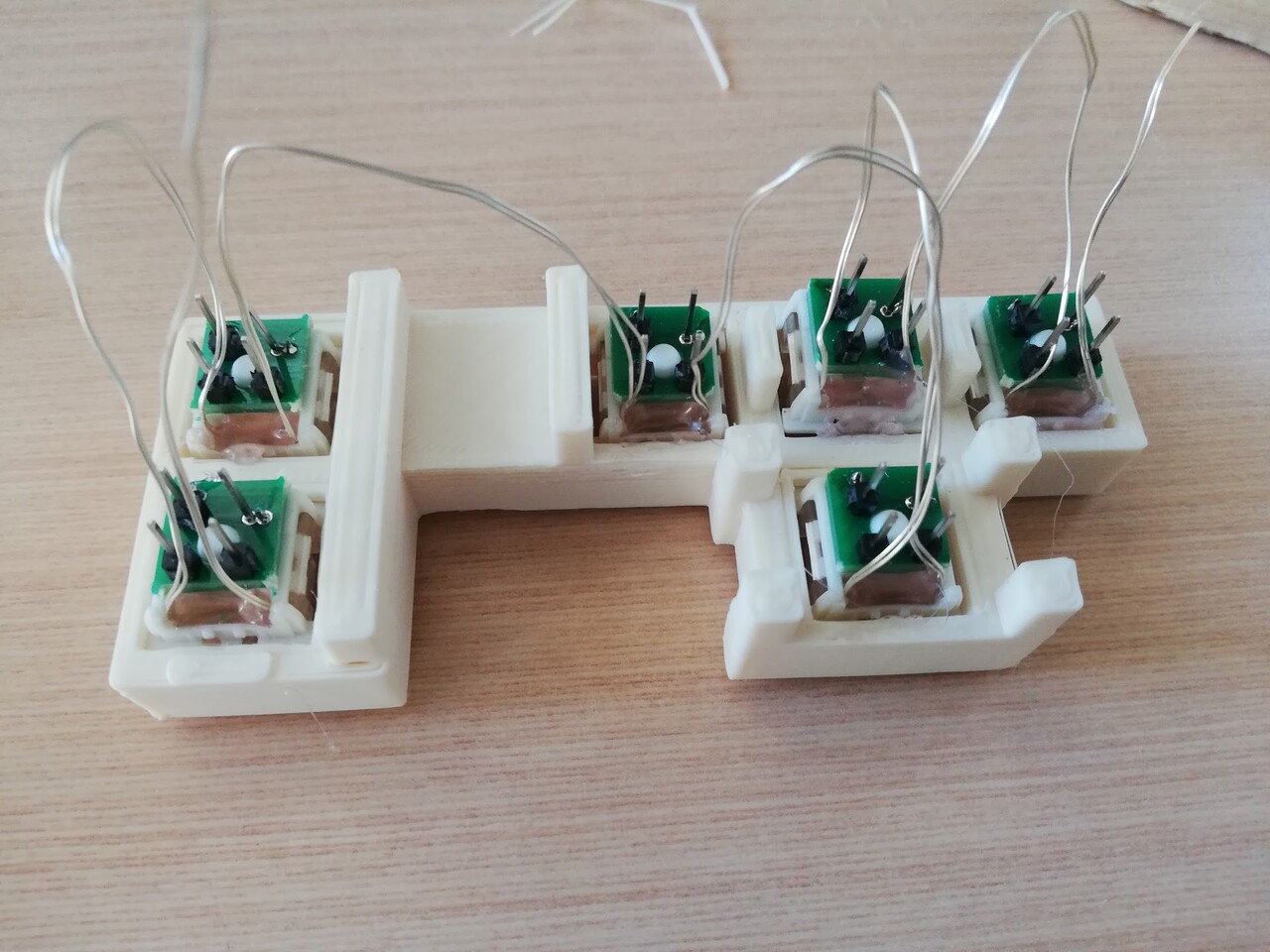

Next I 3d printed a template to make the perfect alignment for the keys before soldering them.

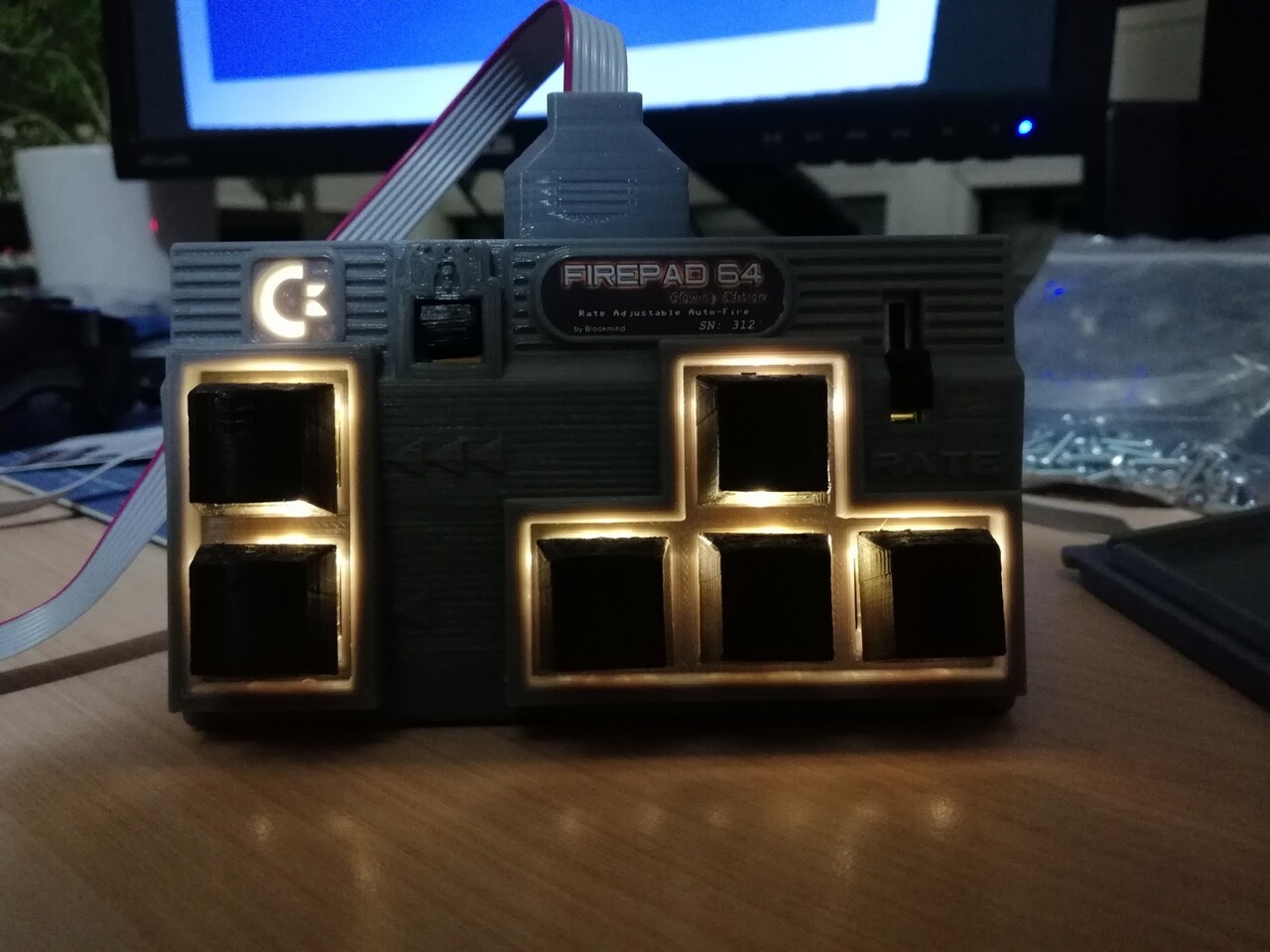

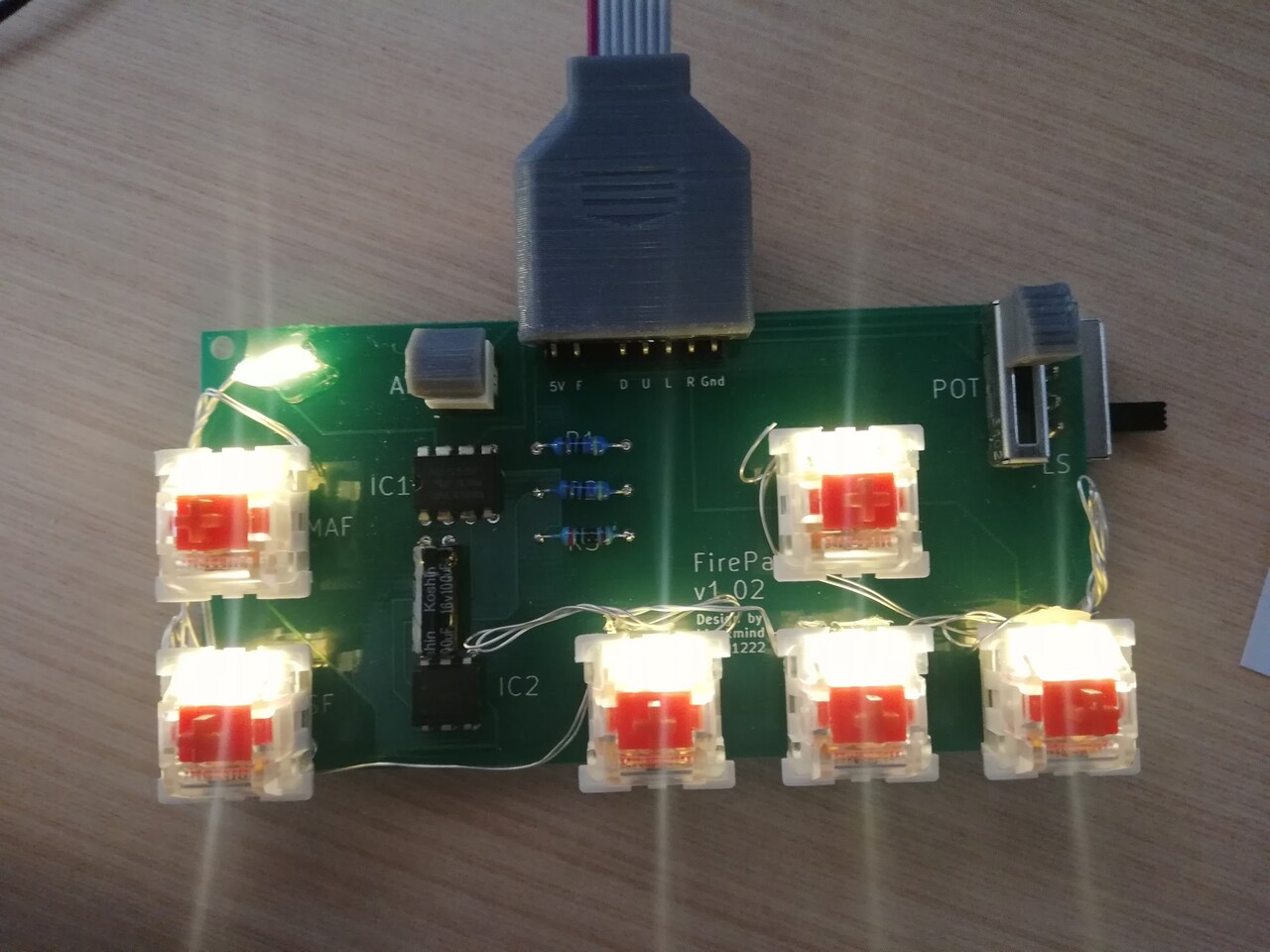

You can see the lighting under the keys. Best part of these mechanical keys, they are designed for to let the light under them. So I used a serial light cable which are used on new year lighting applications on homes to make the keys lit.

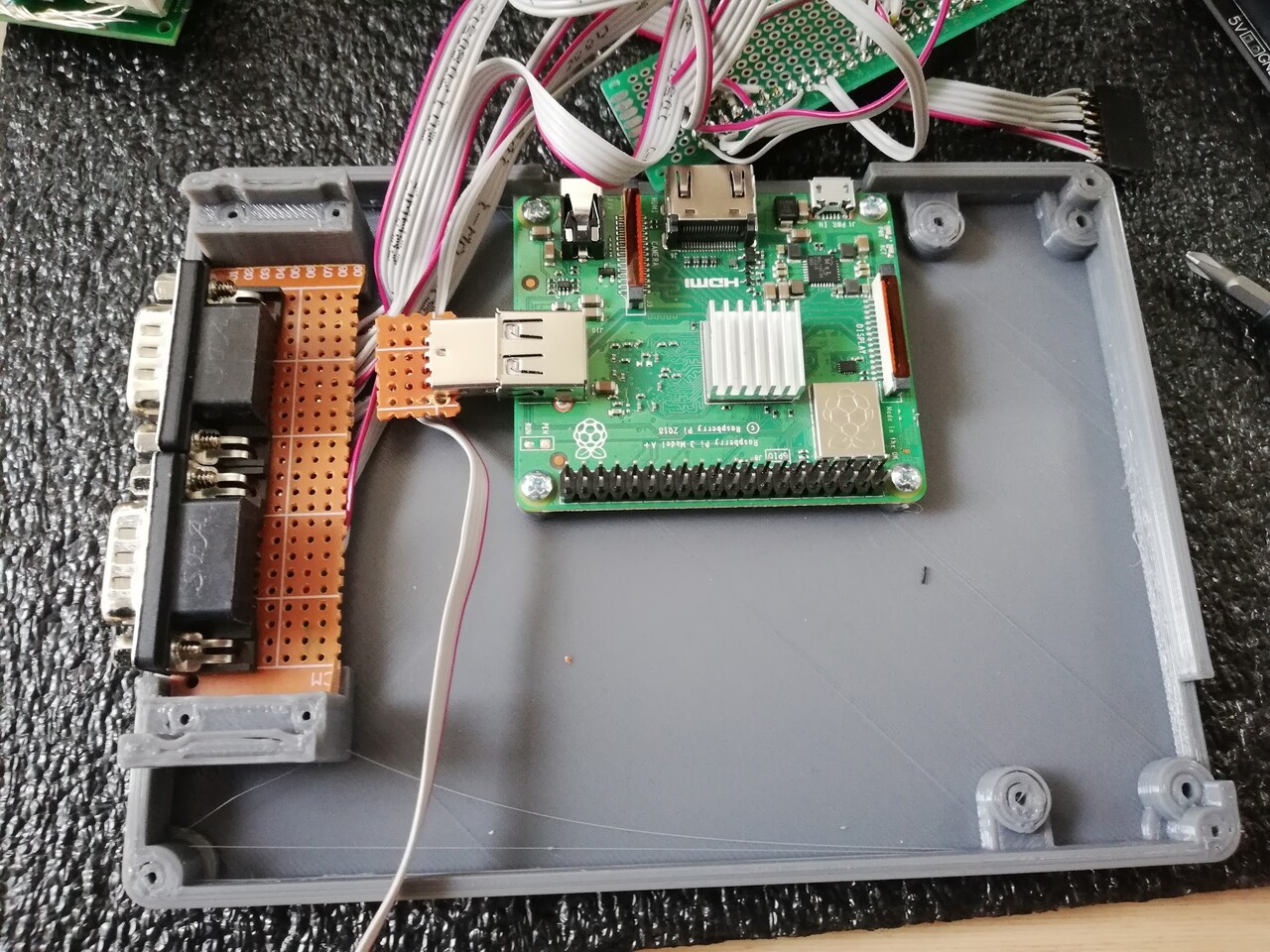

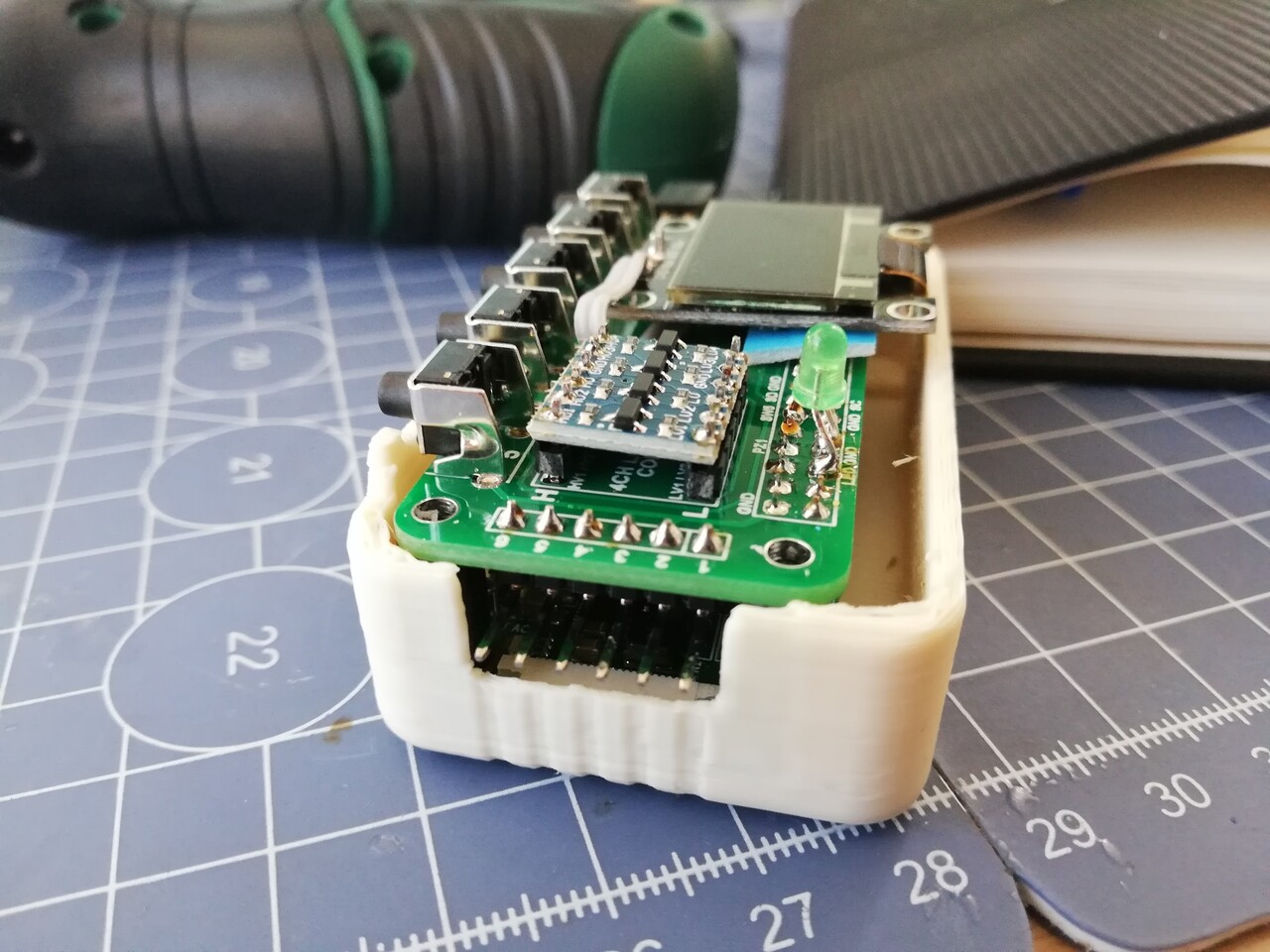

I assembled the PCBs.

This is how they shine like a Christmas tree :)

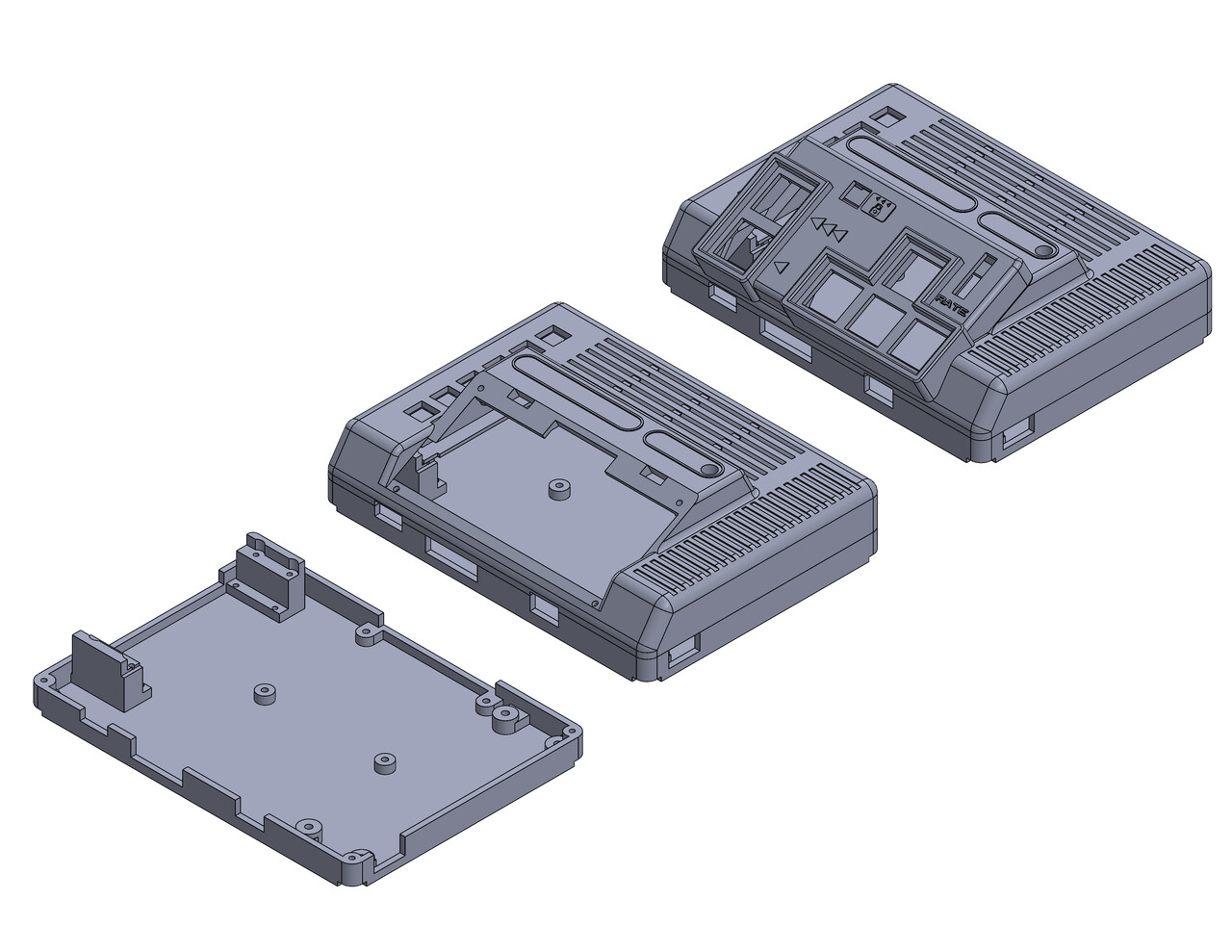

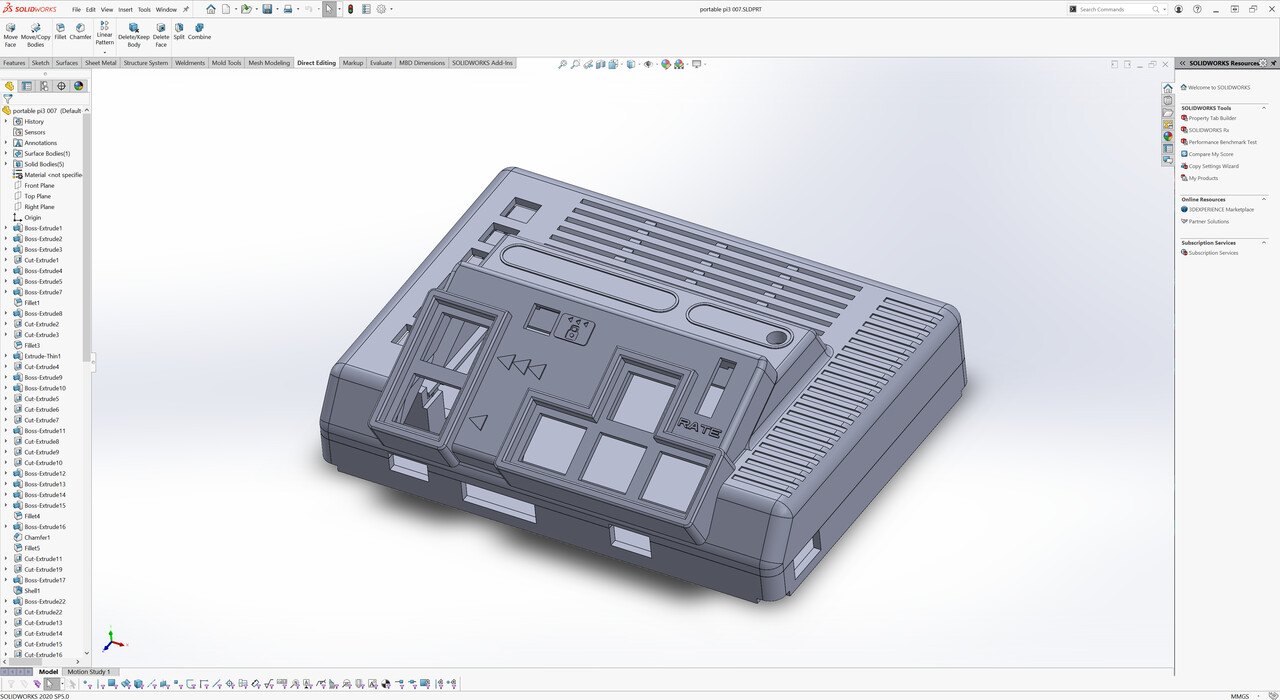

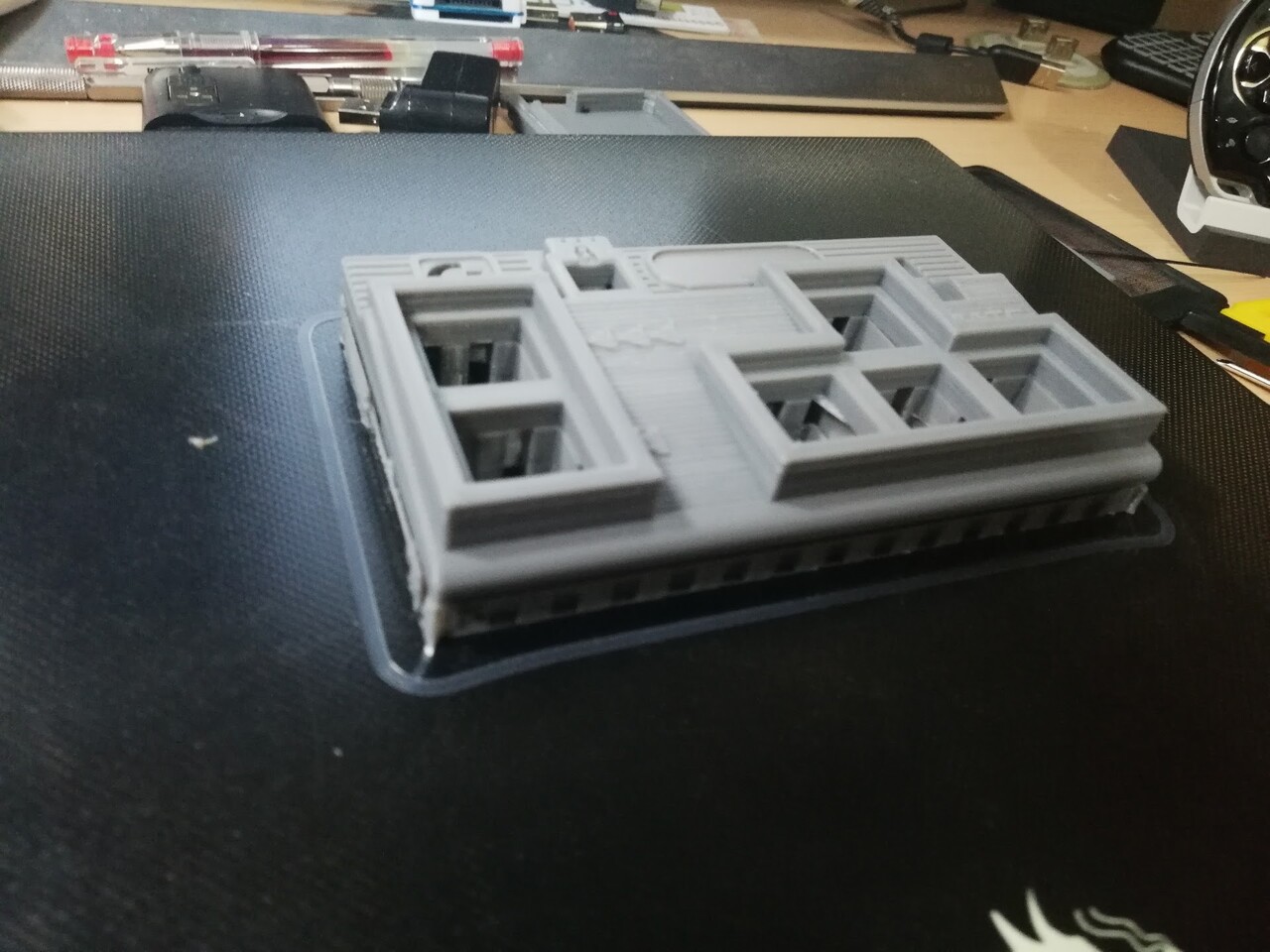

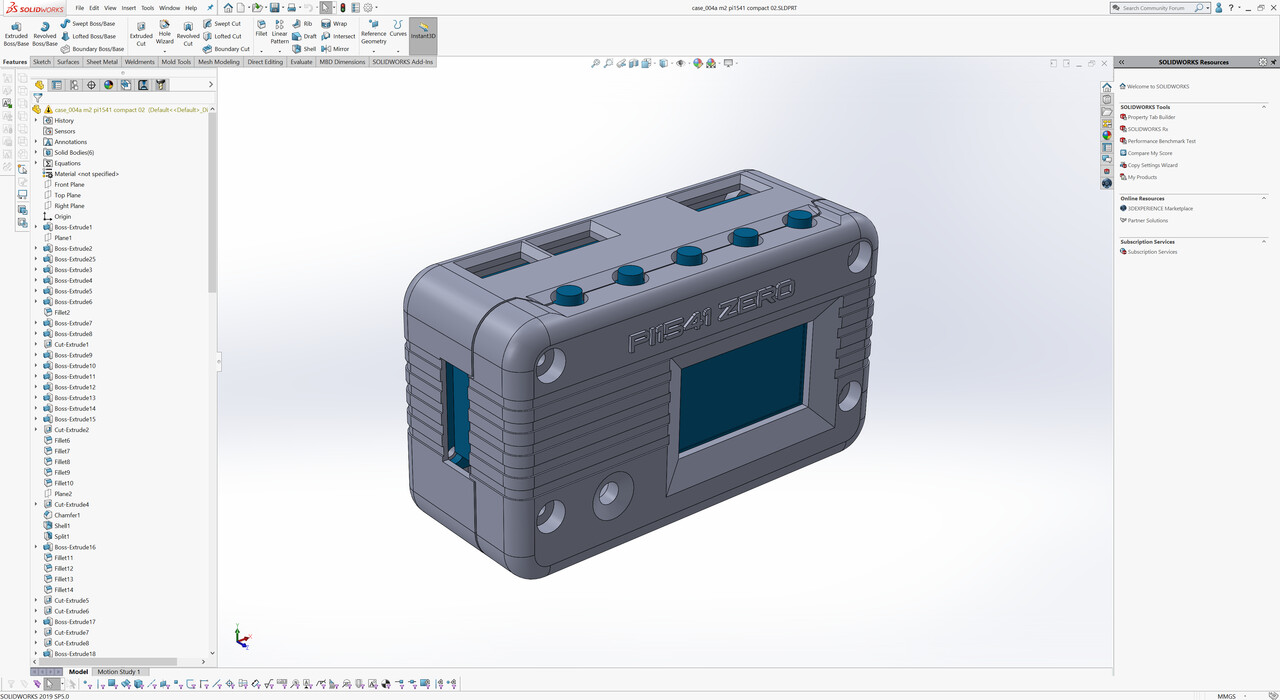

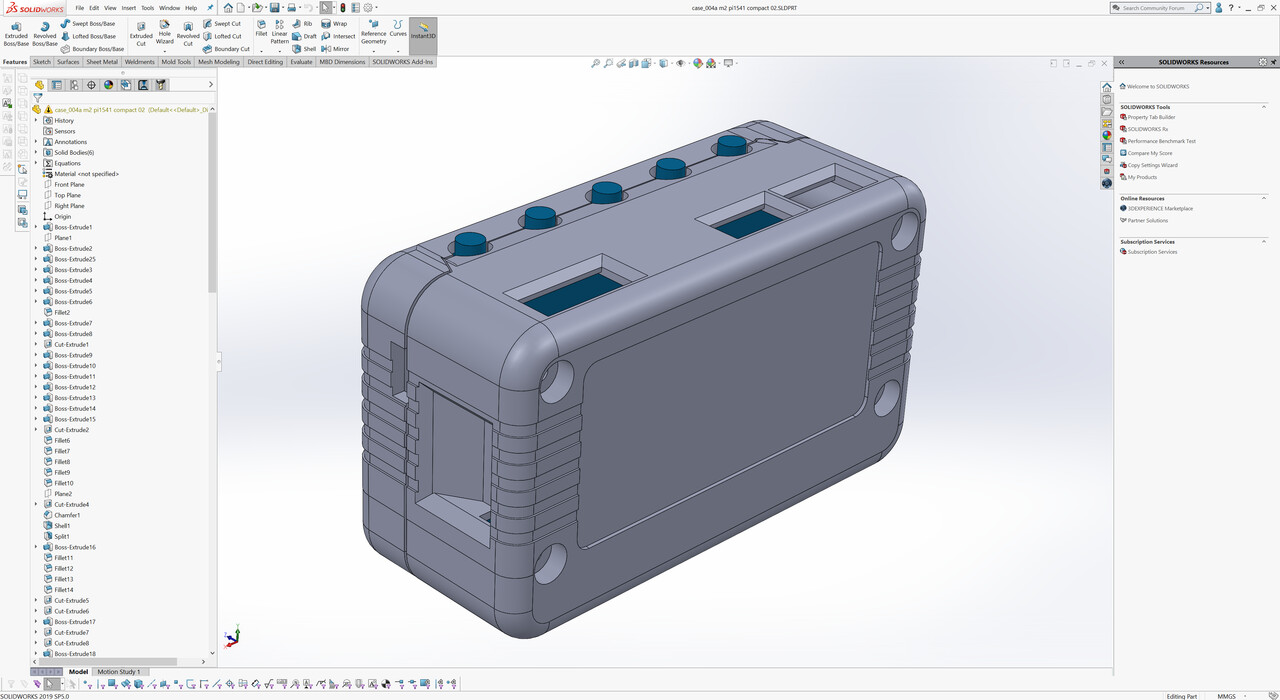

My next step was to finalize the 3d design and make the 3d printing. I made the whole design with Solidworks but I love how Rhinoceros show the CAD models. Look at this fast AO computation in viewport!

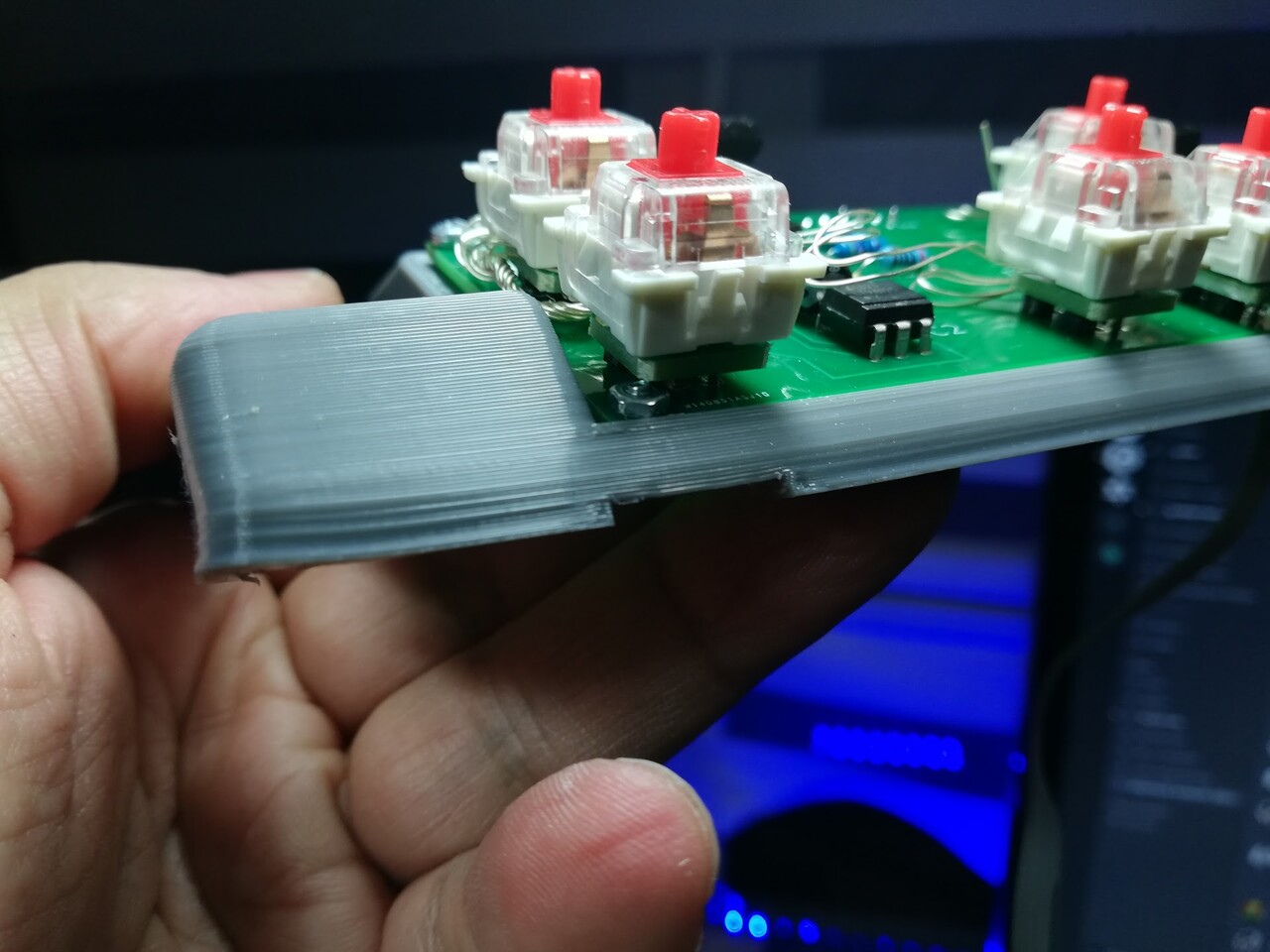

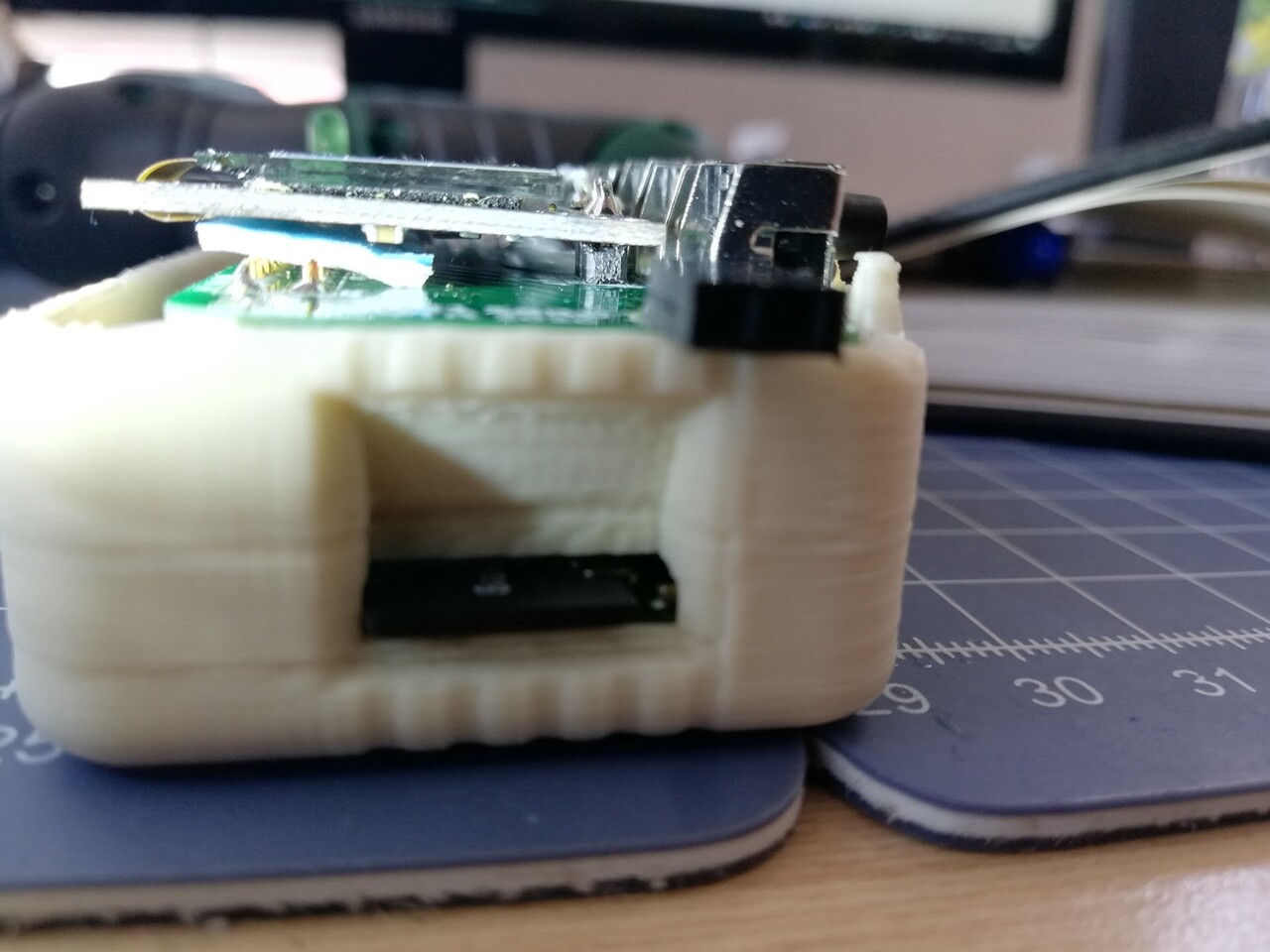

So I started 3d printing and assembled each set after they're complete.

Nice part about these keys is you can use regular keycaps.

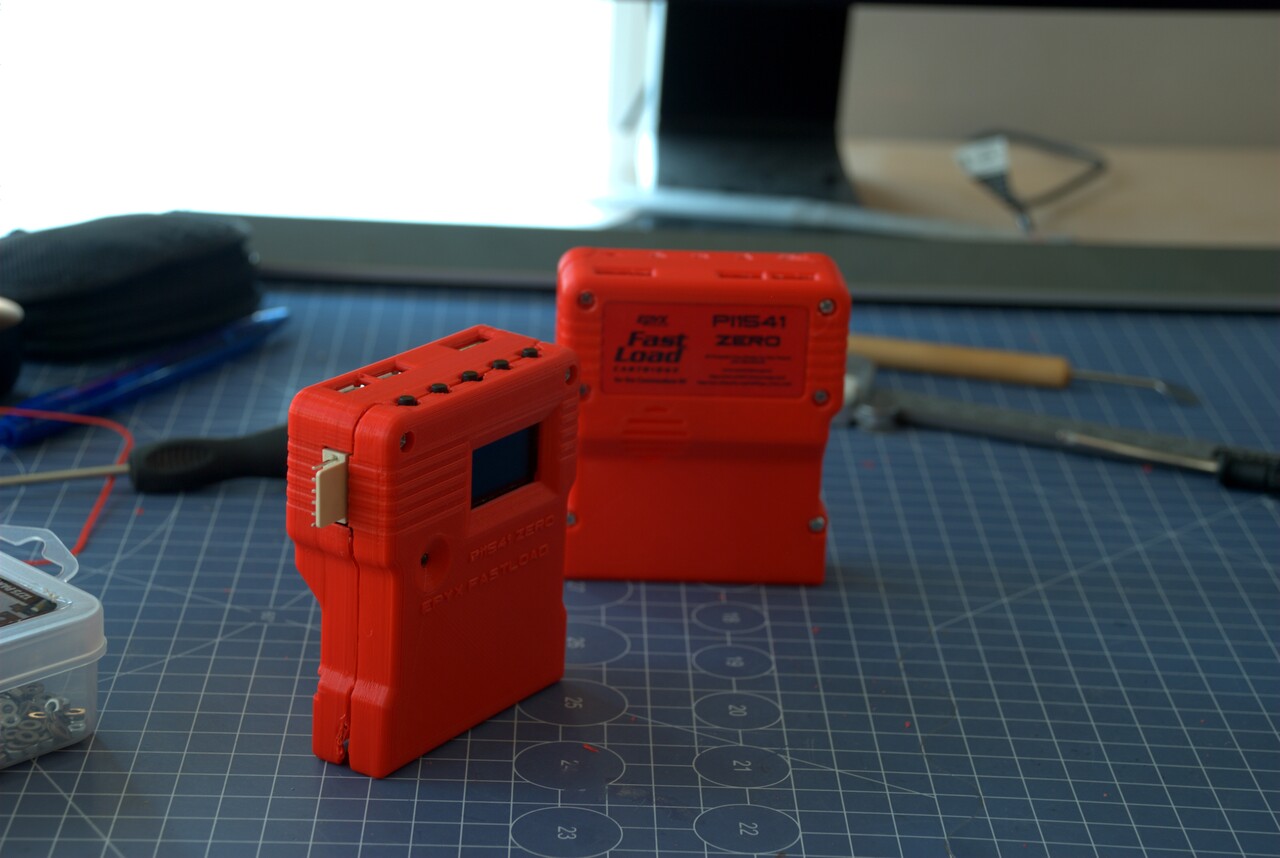

So here is the army of Firepads :)

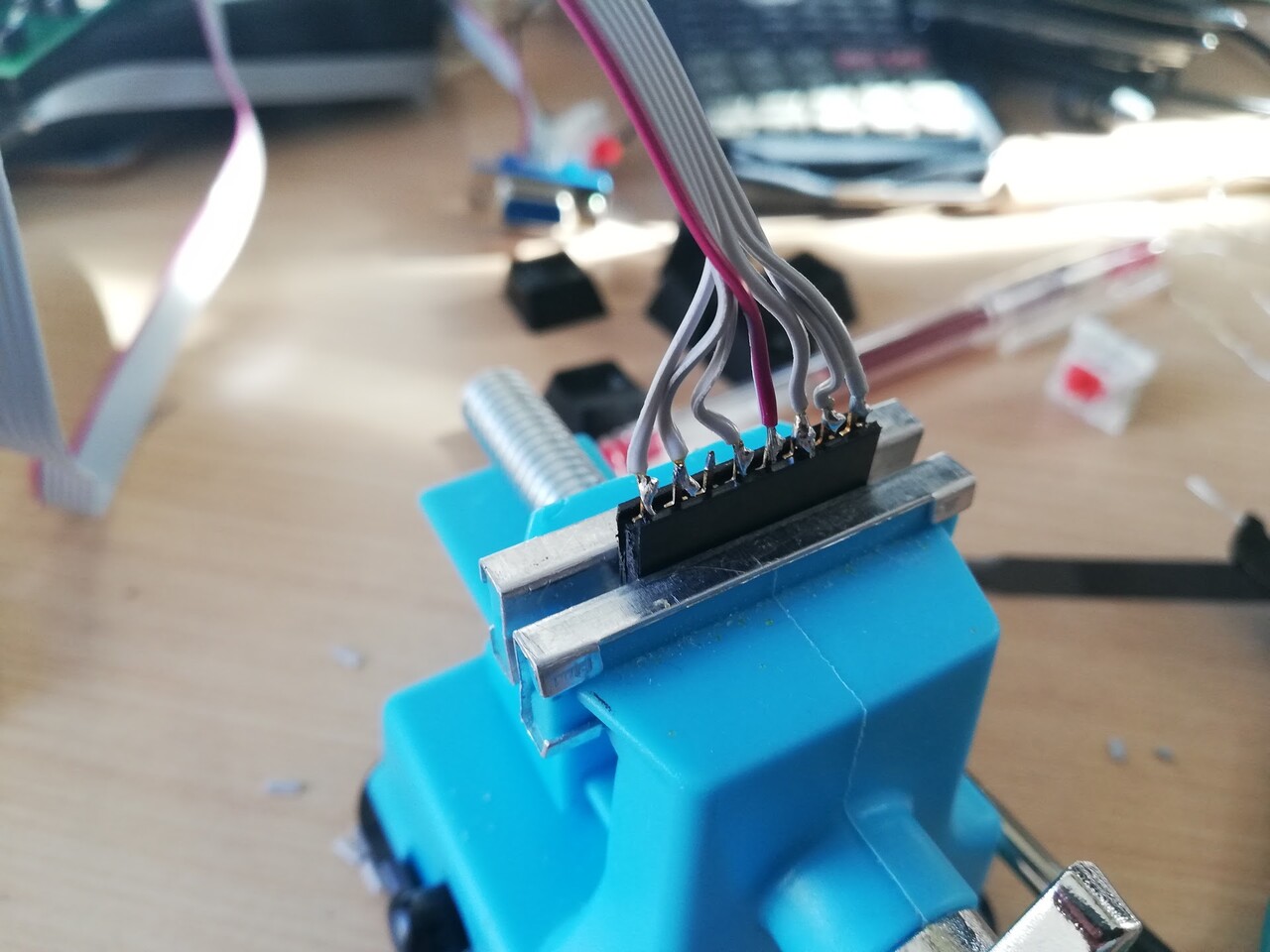

And finally the connector & cable design.

Time for boxing.

Enjoying Mr. Steven Wilson's great music while working on the stickers and product sheets.

...and voila!

I hope you like the steps of this home production phase for some friends from the community of retro gaming. Thanks & see you!